EP0615921A1 - Rigid cartridge for coffee or the like - Google Patents

Rigid cartridge for coffee or the like Download PDFInfo

- Publication number

- EP0615921A1 EP0615921A1 EP94301758A EP94301758A EP0615921A1 EP 0615921 A1 EP0615921 A1 EP 0615921A1 EP 94301758 A EP94301758 A EP 94301758A EP 94301758 A EP94301758 A EP 94301758A EP 0615921 A1 EP0615921 A1 EP 0615921A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- package

- water

- beverage

- coffee

- side wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/70—Containers, packaging elements or packages, specially adapted for particular articles or materials for materials not otherwise provided for

- B65D85/804—Disposable containers or packages with contents which are mixed, infused or dissolved in situ, i.e. without having been previously removed from the package

- B65D85/8043—Packages adapted to allow liquid to pass through the contents

- B65D85/8055—Means for influencing the liquid flow inside the package

Definitions

- the present invention relates to beverage packages and, in particular, to beverage packages containing leaf tea or ground coffee which are intended to provide an infusion of tea or coffee, respectively.

- Freshly brewed coffee may be prepared by the continuous passage of hot water through roast and ground coffee contained in a filter and the coffee collected in a jug or other receptacle, or by percolation which involves the continuous recycling of water through the roast and ground coffee.

- Cartridges containing roast and ground coffee in which hot water flows under gravimetric force through the cartridge are also known.

- a cartridge of this general type is described in British Patent No. 1397116.

- the cartridges for use in "espresso" machines and those through which water flows under gravimetric force contain a filter positioned beneath the charge of coffee.

- water is generally injected into the coffee containing cartridge through a needle.

- the cartridge is filled with water which flows through the filter and is collected in a cup or other receptacle.

- U.S. Patent No. 4446158 describes a disposable individual beverage forming container and filter unit comprising a flat frame having an apertured centre section, filter layers covering the top and bottom of the frame and being secured thereto, and individual quantities of coffee received in compartments formed in the frame between spider-like centre sections thereof.

- U.S. Patents Nos. 4996066 and 5002676 describe cassettes for producing a beverage, such as coffee, for use with a liquid receptacle having an internal locking flange.

- the cassette includes a plurality of ribs connected to an extending across the ring and separating the interior thereof into a multitude of sections.

- leaf tea or ground coffee in so called tea bags or coffee bags which generally comprise leaf tea or ground coffee enclosed between two pieces of a filter material which are sealed around their edges to form a bag.

- Both the cartridges or capsules containing compacted roast and ground coffee and the tea bags or coffee bags suffer from the disadvantage that in order to obtain a beverage of the appropriate strength from the cartridge, capsule or bag it is necessary for the leaf tea or roast and ground coffee contained therein to be wetted uniformly so that uniform extraction of the leaf tea or roast and ground coffee takes place. It is known that the efficiency of extraction from the roast and ground coffee depends upon estalishing a uniform water flow from the start of the infusion process. As soon as coffee is wetted, its volume increases such than any voids in the coffee become filled by the expanded coffee and thereafter water flow is regulated through the coffee bed. Unless, however, the coffee bed is uniformly wetted, this condition is never reached. A means must be provided be distribute water flow evenly into the dry coffee bed.

- the present invention provides a semi-rigid beverage package containing one or more beverage ingredients which package comprises a top, a bottom and a side wall portion the top and the bottom being made from one or more layers of the same or different water-permeable materials and at least one of the top or the bottom of the package being provided with areas formed therein which are impermeable or of varying permeability to the flow of water, whereby, in use, water flows through the package in a pre-determined flow pattern to achieve immediate wetting of the total contents of the package.

- the flow pattern of water through the package may be controlled not only by providing areas in the top of the package which are impermeable or of varying permeability to water, but alternatively or in addition thereto by providing areas in the bottom of the package which are impermeable or of varying permeability to water.

- the pressure drop through the package in the direction of the normal flow of water through the package is increased which causes the water to spread out at right angles to the direction of its normal flow and fill the package.

- the top and bottom of the package are made from the same or different water-permeable materials, preferably a water-permeable synthetic material which is heat sealable.

- suitable water-permeable synthetic materials comprise a spun-bonded non-woven polypropylene sold under the Trade Name COROVIN, a spun-bonded polyester sold under the Trade Name REMAY and a spun-bonded nylon web sold under the Trade Name CEREX. Melt blown polypropylene may also be used.

- Other materials which may also be used include cellulosic materials coated with a material which is activated by heat, or polyethylene or polypropylene perforated films.

- the areas in the top and/or the bottom of the package which are impermeable to the flow of water may be formed by applying heat to a heat sealable water-permeable synthetic material in a predetermined pattern, which treatment, if carried out above the melting point of the synthetic material, will cause the synthetic material to melt and fuse together.

- the impermeable areas may be formed by laminating an appropriate material to the top and/or the bottom of the package in a predetermined pattern.

- the side wall of the package may be formed from a water-permeable material but preferably is formed from a water-impermeable material or a water-permeable material treated to modify its permeability which thus improves the flow of water through the package since water flows through the side wall of the package in a controlled fashion.

- Suitable examples of water-impermeable materials for the formation of the side wall are polypropylene, polyethylene, polyester, etc., or a heat and pressure treated water-permeable material.

- the beverage packages of the present invention may be used in different situations, for example as one-cup filters using gravity, plunging brewing using the cafetiere system or low pressure brewing using pressure pump pots.

- the package of the present invention may be produced in different sizes in order to give different serving options. For example, a package containing about 30 grams of roast and ground coffee will produce 5 cups of coffee, a package containing about 20 grams of roast and ground coffee will produce 3 cups of coffee, whilst a package containing about 7 grams of roast and ground coffee will produce 1 cup of coffee.

- a beverage package in accordance with the present invention is generally shown at 1.

- the package comprises a top 2 and a bottom 3 which are joined by a side wall 4.

- the top portion has a rim or flange 5 which extends beyond the side wall portion.

- the flange can also be seen in the plan view of Figure 3 and the side view of the package given in Figure 4.

- the base portion 3 has areas 6 which are impermeable to the flow of water therethrough. Water will thus flow through the base portion only in the areas of the base between the portions 6 thereof.

- the beverage package of the present invention is filled with a beverage ingredient, for example roast and ground coffee as shown at 7.

- a beverage ingredient for example roast and ground coffee as shown at 7.

- the beverage package as shown in Figures 1 to 4 of the drawings is formed using a heat sealable material.

- the base portion 3 and side wall portion 4 of the package are formed by press forming a heat sealable material into the desired cup shape using heat and pressure to deform the material, as desired.

- the material is held for a set period of time above its normal forming temperature and then allowed to cool when it retains the shape of the former.

- polypropylene the forming of the base and side wall may be carried out at a temperature of 130°C at 80 bar pressure for 9 seconds.

- the areas of the base as shown at 6 are subjected to a higher temperature of above 137°C (the melting temperature of polypropylene) in order to melt the web and thus form the water-impermeable areas 6.

- the shaped body comprising the base 3 and side wall portion 4 of the package is then filled with the roast and ground coffee 7 and the top 2 of the package heat sealed to the top of the side wall 4, thus completing the package.

- the forming of the polypropylene into the base 3 and side wall 4 in a single operation provides a semi-rigid structure and this enables the package to be filled very compactly with the beverage ingredient.

- water-impermeable areas 6 of the base 3 of the capsule are also formed as corrugations and this helps to increase the rigidity of the package.

- the beverage package is generally shown at 10 and has a top 11, a bottom 12 and a side wall portion 13.

- the side wall is formed from a closed pore material to improve the flow of water through the coffee bed.

- a closed pore material may be produced by using a water-permeable material and subjecting all or a part of the surface to heat and pressure.

- the side wall is also semi-rigid.

- the side wall 13 is formed as shown in Figure 5 with an inwardly extending rim or flange 14 at the bottom thereof and an outwardly extending rim or flange 15 at the top thereof. These rims or flanges are provided for heat sealing to the bottom 12 and top 11, respectively.

- the top 11 and bottom 12 of the beverage package of this embodiment are generally similar to the top 2 and bottom 3 of the beverage package as shown with reference to Figures 1 to 4.

- the bottom is thus provided with areas 17 which are made water-impermeable by a suitable heat treatment of the material from which the base 12 is formed.

- the beverage package is filled with a beverage ingredient 16, as shown.

- the bottom 12 of the beverage package is sealed to the rim 14 of the side wall 13 as a first operation, the desired amount of beverage ingredient 16 is then introduced into the package and the top 11 is then sealed into position on rim 15 of the side wall 13, so completing the package.

- a beverage package generally shown at 20 comprises a top 21 a bottom 22 and a sidewall 23.

- the top 21 has a water-impermeable central portion 24.

- the beverage package is generally divided into two compartments 25 and 26 as shown in Figure 7E.

- the compartments are formed by a conical section of water-permeable material 27 being positioned between the top of the beverage package 21 and the bottom of the beverage package 22.

- the side wall 23 of the beverage package is formed from a water-impermeable material in order to encourage an even flow of water through the beverage package as shown in Figure 7E.

- the beverage packages of the present invention may contain any desired beverage ingredients, for example, roast and ground coffee, leaf tea, chocolate powder and, according to individual taste, powdered milk or creamer, sugar and/or an artificial sweetner.

- beverage ingredients for example, roast and ground coffee, leaf tea, chocolate powder and, according to individual taste, powdered milk or creamer, sugar and/or an artificial sweetner.

Abstract

A semi-rigid beverage package containing one or more beverage ingredients which package (10) comprises a top (11), a bottom (12) and a side wall portion (13) the top (11) and the bottom (12) being made from one or more layers of the same or different water-permeable materials and at least one of the top (11) or the bottom (12) of the package (10) being provided with areas formed therein which are impermeable (6) or of varying permeability to the flow of water, whereby, in use, water flows through the package (10) in a pre-determined flow pattern to achieve immediate wetting of the total contents (16) of the package.

The beverage package (10) preferably contains leaf tea or roast and ground coffee.

Description

- The present invention relates to beverage packages and, in particular, to beverage packages containing leaf tea or ground coffee which are intended to provide an infusion of tea or coffee, respectively.

- The production of freshly brewed tea or coffee involves contacting tea leaves or roast and ground coffee with hot water and separating the beverage from the tea leaves or coffee grounds. Various methods for the production of freshly brewed coffee or tea are well known. For example, tea is prepared traditionally in a teapot, the tea leaves being immersed in boiling water and allowed to stand before being poured from the pot. Freshly brewed coffee may be prepared by the continuous passage of hot water through roast and ground coffee contained in a filter and the coffee collected in a jug or other receptacle, or by percolation which involves the continuous recycling of water through the roast and ground coffee.

- It has previously been proposed to seal fresh roast and ground coffee or tea leaves in individual air-impermeable packages. For example, cartridges or capsules containing compacted ground coffee are known for use in certain coffee making machines which are generally termed "espresso" machines. In the production of coffee using these coffee machines the coffee cartridge is placed in a brewing chamber and hot water is generally caused to pass under pressure through the cartridge, thereby extracting the aromatic coffee constitutents from the ground coffee and producing a coffee beverage.

- Cartridges containing roast and ground coffee in which hot water flows under gravimetric force through the cartridge are also known. A cartridge of this general type is described in British Patent No. 1397116.

- The cartridges for use in "espresso" machines and those through which water flows under gravimetric force contain a filter positioned beneath the charge of coffee. In the production of coffee from these cartridges water is generally injected into the coffee containing cartridge through a needle. The cartridge is filled with water which flows through the filter and is collected in a cup or other receptacle.

- U.S. Patent No. 4446158 describes a disposable individual beverage forming container and filter unit comprising a flat frame having an apertured centre section, filter layers covering the top and bottom of the frame and being secured thereto, and individual quantities of coffee received in compartments formed in the frame between spider-like centre sections thereof.

- U.S. Patents Nos. 4996066 and 5002676 describe cassettes for producing a beverage, such as coffee, for use with a liquid receptacle having an internal locking flange. The cassette includes a plurality of ribs connected to an extending across the ring and separating the interior thereof into a multitude of sections.

- It is also well known to package leaf tea or ground coffee in so called tea bags or coffee bags which generally comprise leaf tea or ground coffee enclosed between two pieces of a filter material which are sealed around their edges to form a bag.

- Both the cartridges or capsules containing compacted roast and ground coffee and the tea bags or coffee bags suffer from the disadvantage that in order to obtain a beverage of the appropriate strength from the cartridge, capsule or bag it is necessary for the leaf tea or roast and ground coffee contained therein to be wetted uniformly so that uniform extraction of the leaf tea or roast and ground coffee takes place. It is known that the efficiency of extraction from the roast and ground coffee depends upon estalishing a uniform water flow from the start of the infusion process. As soon as coffee is wetted, its volume increases such than any voids in the coffee become filled by the expanded coffee and thereafter water flow is regulated through the coffee bed. Unless, however, the coffee bed is uniformly wetted, this condition is never reached. A means must be provided be distribute water flow evenly into the dry coffee bed.

- We have now developed a beverage package which is adapted to provide a predetermined flow path for water into and through the beverage ingredients contained therein which controls the wetting of the leaf tea or roast and ground coffee and thus controls the extraction of the leaf tea or ground coffee to form the beverage.

- Accordingly, the present invention provides a semi-rigid beverage package containing one or more beverage ingredients which package comprises a top, a bottom and a side wall portion the top and the bottom being made from one or more layers of the same or different water-permeable materials and at least one of the top or the bottom of the package being provided with areas formed therein which are impermeable or of varying permeability to the flow of water, whereby, in use, water flows through the package in a pre-determined flow pattern to achieve immediate wetting of the total contents of the package.

- The flow pattern of water through the package may be controlled not only by providing areas in the top of the package which are impermeable or of varying permeability to water, but alternatively or in addition thereto by providing areas in the bottom of the package which are impermeable or of varying permeability to water. By limiting the flow pattern of the beverage leaving the package, the pressure drop through the package in the direction of the normal flow of water through the package is increased which causes the water to spread out at right angles to the direction of its normal flow and fill the package.

- The top and bottom of the package are made from the same or different water-permeable materials, preferably a water-permeable synthetic material which is heat sealable. Examples of suitable water-permeable synthetic materials comprise a spun-bonded non-woven polypropylene sold under the Trade Name COROVIN, a spun-bonded polyester sold under the Trade Name REMAY and a spun-bonded nylon web sold under the Trade Name CEREX. Melt blown polypropylene may also be used. Other materials which may also be used include cellulosic materials coated with a material which is activated by heat, or polyethylene or polypropylene perforated films.

- The areas in the top and/or the bottom of the package which are impermeable to the flow of water may be formed by applying heat to a heat sealable water-permeable synthetic material in a predetermined pattern, which treatment, if carried out above the melting point of the synthetic material, will cause the synthetic material to melt and fuse together. Alternatively the impermeable areas may be formed by laminating an appropriate material to the top and/or the bottom of the package in a predetermined pattern.

- The side wall of the package may be formed from a water-permeable material but preferably is formed from a water-impermeable material or a water-permeable material treated to modify its permeability which thus improves the flow of water through the package since water flows through the side wall of the package in a controlled fashion. Suitable examples of water-impermeable materials for the formation of the side wall are polypropylene, polyethylene, polyester, etc., or a heat and pressure treated water-permeable material.

- The beverage packages of the present invention may be used in different situations, for example as one-cup filters using gravity, plunging brewing using the cafetiere system or low pressure brewing using pressure pump pots.

- The package of the present invention may be produced in different sizes in order to give different serving options. For example, a package containing about 30 grams of roast and ground coffee will produce 5 cups of coffee, a package containing about 20 grams of roast and ground coffee will produce 3 cups of coffee, whilst a package containing about 7 grams of roast and ground coffee will produce 1 cup of coffee.

- The method of forming the packages of the present invention will be described with reference to the accompanying drawings, in which:

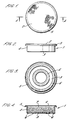

- Figure 1 shows a top plan view of a first beverage package in accordance with the invention;

- Figure 2 shows a side view of a first beverage package in accordance with the invention;

- Figure 3 shows a bottom plan view of a first beverage package in accordance with the invention;

- Figure 4 is a section through a first beverage package of the invention along line A-A of Figure 1; and

- Figure 5 illustrates the side wall portion of a beverage package according to a second embodiment of the invention;

- Figure 6 illustrates a sectional view of a beverage package according to a second embodiment of the invention; and

- Figures 7A to 7E illustrate a beverage package according to a third embodiment of the invention.

- Referring to Figures 1 to 4 of the drawings, a beverage package in accordance with the present invention is generally shown at 1.

- The package comprises a top 2 and a

bottom 3 which are joined by a side wall 4. The top portion has a rim orflange 5 which extends beyond the side wall portion. The flange can also be seen in the plan view of Figure 3 and the side view of the package given in Figure 4. - In the embodiment as shown in the drawings the

base portion 3 has areas 6 which are impermeable to the flow of water therethrough. Water will thus flow through the base portion only in the areas of the base between the portions 6 thereof. - As shown in the section of Figure 4 the beverage package of the present invention is filled with a beverage ingredient, for example roast and ground coffee as shown at 7.

- The beverage package as shown in Figures 1 to 4 of the drawings is formed using a heat sealable material. The

base portion 3 and side wall portion 4 of the package are formed by press forming a heat sealable material into the desired cup shape using heat and pressure to deform the material, as desired. The material is held for a set period of time above its normal forming temperature and then allowed to cool when it retains the shape of the former. Using polypropylene the forming of the base and side wall may be carried out at a temperature of 130°C at 80 bar pressure for 9 seconds. - The areas of the base as shown at 6 are subjected to a higher temperature of above 137°C (the melting temperature of polypropylene) in order to melt the web and thus form the water-impermeable areas 6.

- The shaped body comprising the

base 3 and side wall portion 4 of the package is then filled with the roast and ground coffee 7 and the top 2 of the package heat sealed to the top of the side wall 4, thus completing the package. - The forming of the polypropylene into the

base 3 and side wall 4 in a single operation provides a semi-rigid structure and this enables the package to be filled very compactly with the beverage ingredient. - It will be noted that the water-impermeable areas 6 of the

base 3 of the capsule are also formed as corrugations and this helps to increase the rigidity of the package. - Referring to Figures 5 and 6 of the accompanying drawings, a second embodiment of a beverage package according to the invention is shown.

- The beverage package is generally shown at 10 and has a

top 11, abottom 12 and aside wall portion 13. - As shown in Figure 5, the side wall is formed from a closed pore material to improve the flow of water through the coffee bed. A closed pore material may be produced by using a water-permeable material and subjecting all or a part of the surface to heat and pressure. The side wall is also semi-rigid. The

side wall 13 is formed as shown in Figure 5 with an inwardly extending rim orflange 14 at the bottom thereof and an outwardly extending rim orflange 15 at the top thereof. These rims or flanges are provided for heat sealing to the bottom 12 and top 11, respectively. - The top 11 and bottom 12 of the beverage package of this embodiment are generally similar to the top 2 and

bottom 3 of the beverage package as shown with reference to Figures 1 to 4. The bottom is thus provided withareas 17 which are made water-impermeable by a suitable heat treatment of the material from which thebase 12 is formed. The beverage package is filled with abeverage ingredient 16, as shown. - It will be understood that the bottom 12 of the beverage package is sealed to the

rim 14 of theside wall 13 as a first operation, the desired amount ofbeverage ingredient 16 is then introduced into the package and the top 11 is then sealed into position onrim 15 of theside wall 13, so completing the package. - Referring to Figure 7A to 7E, a beverage package generally shown at 20 comprises a top 21 a bottom 22 and a

sidewall 23. The top 21 has a water-impermeablecentral portion 24. The beverage package is generally divided into twocompartments permeable material 27 being positioned between the top of thebeverage package 21 and the bottom of thebeverage package 22. - As will be seen from Figures 7A to 7D the component parts of the beverage package are stacked together in the order as shown and the top of the

beveage package 21 heat sealed to therim 28 of theside wall 23, whilst the combination of thebase 22 andcone 27 are heat sealed to the bottomannular rim 29 of theside wall 23. - As shown in Figure 7E, when the

beverage package 20 is used with water flowing in an upward direction, the waterimpermeable centre 24 of the top 21 causes the water flow to be diverted through the package in the direction as shown by the arrows. - The provision in the package of

separate compartments - The

side wall 23 of the beverage package is formed from a water-impermeable material in order to encourage an even flow of water through the beverage package as shown in Figure 7E. - The beverage packages of the present invention may contain any desired beverage ingredients, for example, roast and ground coffee, leaf tea, chocolate powder and, according to individual taste, powdered milk or creamer, sugar and/or an artificial sweetner.

Claims (6)

- A semi-rigid beverage package containing one or more beverage ingredients which package comprises a top, a bottom and a side wall portion the top and the bottom being made from one or more layers of the same or different water-permeable materials and at least one of the top or the bottom of the package being provided with areas formed therein which are impermeable or of varying permeability to the flow of water, whereby, in use, water flows through the package in a pre-determined flow pattern to achieve immediate wetting of the total contents of the package.

- A package as claimed in claim 1 wherein the top and the bottom are made from the same or different heat-sealable water-permeable materials.

- A package as claimed in claim 1 or claim 2 wherein the top and/or the bottom is made from a plurality of layers of the same or different heat-sealable water-permeable materials.

- A package as claimed in claim 2 or claim 3 wherein the heat-sealable material is spun-bonded or melt blown polypropylene, spun-bonded polyester or spun-bonded nylon.

- A package as claimed in any one of the preceding claims wherein the side wall is formed from a water-impermeable material.

- A package as claimed in any one of the preceding claims which contains leaf tea or roast and ground coffee.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB939305461A GB9305461D0 (en) | 1993-03-17 | 1993-03-17 | Beverage packages |

| GB9305461 | 1993-03-17 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0615921A1 true EP0615921A1 (en) | 1994-09-21 |

Family

ID=10732195

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94301758A Withdrawn EP0615921A1 (en) | 1993-03-17 | 1994-03-11 | Rigid cartridge for coffee or the like |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0615921A1 (en) |

| JP (1) | JPH06315437A (en) |

| AU (1) | AU5649794A (en) |

| CA (1) | CA2119178A1 (en) |

| GB (1) | GB9305461D0 (en) |

Cited By (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5633026A (en) * | 1991-07-05 | 1997-05-27 | The Procter & Gamble Company | Tea filter pack for automatic brewers |

| US6139883A (en) * | 1995-07-29 | 2000-10-31 | J. R. Crompton Limited | Porous web material |

| US6548433B1 (en) | 1997-02-12 | 2003-04-15 | J. R. Compton Limited | Porous web material |

| EP1529739A1 (en) * | 2003-11-06 | 2005-05-11 | Keurig, Incorporated | Disposable beverage filter package |

| WO2006037062A1 (en) * | 2004-09-24 | 2006-04-06 | The Procter & Gamble Company | Liquid infusion pods containing insoluble materials |

| WO2007042415A1 (en) | 2005-10-14 | 2007-04-19 | Nestec S.A. | Method for preparing a beverage from a capsule |

| WO2007118914A1 (en) * | 2006-04-17 | 2007-10-25 | German Diaz Blanco | Single-use food-grade plastic or aluminium cup system with integral pressed ground coffee for placing in the cavity of an espresso coffee maker. |

| EP1894853A1 (en) | 2006-08-30 | 2008-03-05 | Nestec S.A. | Capsule for the preparation of a beverage |

| EP1961676A2 (en) | 2007-02-14 | 2008-08-27 | Arnoplast S.r.l. | Rigid capsule for coffee or other soluble products with improved lower seal |

| WO2008113779A2 (en) * | 2007-03-19 | 2008-09-25 | Nestec S.A. | Capsule with flow regulating technology |

| EP2030915A3 (en) * | 2007-08-30 | 2009-09-16 | GVB Gesellschaft für Vermögensberatungen AG | Capsule and device for creating liquid food, in particular coffee |

| WO2010126365A1 (en) * | 2009-04-27 | 2010-11-04 | Sara Lee/De N.V. | A pad for preparing a beverage, a container comprising several pads, an apparatus and a method for preparing the beverage |

| US7832328B2 (en) | 2004-08-12 | 2010-11-16 | Sara Lee/De N.V. | System with a fluid path restriction for making a beverage |

| US20100303965A1 (en) * | 2007-09-03 | 2010-12-02 | Alain Mariller | Cartridge for preparing a beverage |

| US7981451B2 (en) | 2005-10-14 | 2011-07-19 | Nestec S.A. | Capsule for the preparation of a beverage |

| US8062682B2 (en) | 2005-11-10 | 2011-11-22 | Nestec S.A. | Beverage ingredient containing capsule having several compartments |

| US8147886B2 (en) | 2002-08-23 | 2012-04-03 | Sara Lee/ De N.V. | Form-retaining pad for preparing a beverage suitable for consumption |

| CN102459031A (en) * | 2009-05-29 | 2012-05-16 | 库里格股份有限公司 | Beverage cartridge with filter guard |

| ES2398278A1 (en) * | 2012-08-28 | 2013-03-15 | Unión Tostadora, S.A. | Capsule for a beverage maker |

| US20130129871A1 (en) * | 2010-05-20 | 2013-05-23 | Teatek Co., Ltd. | Beverage substance cartridge, water filling apparatus, beverage producing equipment, beverage producing system and beverage producing method |

| USD694620S1 (en) | 2011-03-08 | 2013-12-03 | Kraft Foods R&D, Inc. | Beverage cartridge |

| US20140120217A1 (en) * | 2012-10-26 | 2014-05-01 | Printpack Illinois, Inc. | Container With Improved Puncture Design |

| US20140120218A1 (en) * | 2012-10-26 | 2014-05-01 | Printpack Illinois, Inc. | Container With Improved Puncture Design |

| USD708057S1 (en) | 2012-09-10 | 2014-07-01 | Kraft Foods R & D, Inc. | Beverage cartridge |

| WO2014110355A2 (en) * | 2013-01-11 | 2014-07-17 | Dlcr Acquisition, Llc | A beverage cartridge |

| US8850960B2 (en) | 2008-01-29 | 2014-10-07 | Koninklijke Douwe Egberts B.V. | System, method and capsule for preparing a beverage |

| GB2513163A (en) * | 2013-04-18 | 2014-10-22 | British American Tobacco Co | Container |

| WO2014168940A3 (en) * | 2013-04-12 | 2014-12-04 | Printpack Illinois, Inc. | Containers and materials with improved punctureability |

| NL2012063C2 (en) * | 2014-01-08 | 2015-07-09 | Koninkl Douwe Egberts Bv | Form retaining pad for use in a coffee maker. |

| WO2015113758A1 (en) * | 2014-01-29 | 2015-08-06 | Espressocap S.P.A. | Pre-packaged pod of coffee powder |

| US9260238B2 (en) | 2006-08-10 | 2016-02-16 | Koninklijke Douwe Egberts B.V. | Method for providing a beverage provided with a fine-bubble froth layer or a beverage at least virtually without the fine bubble froth layer, pad with covering filled with product to be extracted and/or to be dissolved; assembly provided with such a pad and a holder; beverage preparation apparatus for preparing a beverage |

| US20170101258A1 (en) * | 2014-03-11 | 2017-04-13 | Mars, Incorporated | Beverage preparation capsules |

| US9714136B2 (en) | 2004-04-28 | 2017-07-25 | Koninklijke Douwe Egberts B.V. | Pad and assembly of a holder and such a pad |

| US9783361B2 (en) | 2013-03-14 | 2017-10-10 | Starbucks Corporation | Stretchable beverage cartridges and methods |

| US9877495B2 (en) | 2015-01-09 | 2018-01-30 | Starbucks Corporation | Method of making a sweetened soluble beverage product |

| US9932168B2 (en) | 2011-03-08 | 2018-04-03 | Kraft Foods R & D, Inc. | Beverage delivery pod and methods of use and manufacture |

| WO2018119390A1 (en) * | 2016-12-23 | 2018-06-28 | Ideators, LLC | Printable pattern filters |

| US10336498B2 (en) | 2014-06-10 | 2019-07-02 | Printpack Illinois, Inc. | Container with improved punctureability |

| US10336531B2 (en) * | 2014-03-21 | 2019-07-02 | 2266170 Ontario Inc. | Capsule with steeping chamber |

| US10442610B2 (en) | 2014-03-11 | 2019-10-15 | Starbucks Corporation | Pod-based restrictors and methods |

| US10919691B2 (en) | 2018-04-05 | 2021-02-16 | Ideators, LLC | Beverage cartridge with needle puncture prevention |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU723743B1 (en) * | 1999-09-09 | 2000-09-07 | Tien, Jung-Jung | Tea infusing device |

| PL205052B1 (en) * | 2003-01-24 | 2010-03-31 | Kraft Foods R&D | Cartridge for the preparation of beverages and method of manufacturing a cartridge |

| US7640843B2 (en) | 2003-01-24 | 2010-01-05 | Kraft Foods R & D, Inc. | Cartridge and method for the preparation of beverages |

| PT2443048E (en) * | 2009-06-17 | 2015-08-28 | Koninkl Douwe Egberts Bv | System, method and capsule for preparing a beverage |

| US9527661B2 (en) * | 2009-09-29 | 2016-12-27 | Lbp Manufacturing Llc | Disposable single use beverage package |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3094917A (en) * | 1959-11-17 | 1963-06-25 | Koffie F Rombouts N V | Filtering device for the preparation of infusions, to be used only once |

| GB938617A (en) * | 1959-02-06 | 1963-10-02 | Sealpak Corp | Non-refillable infuser or container and method of using same |

| FR1347892A (en) * | 1962-11-23 | 1964-01-04 | Coffee filter | |

| FR2160634A1 (en) * | 1971-11-19 | 1973-06-29 | Marlet Barrera Jose |

-

1993

- 1993-03-17 GB GB939305461A patent/GB9305461D0/en active Pending

-

1994

- 1994-03-01 AU AU56497/94A patent/AU5649794A/en not_active Abandoned

- 1994-03-11 EP EP94301758A patent/EP0615921A1/en not_active Withdrawn

- 1994-03-16 JP JP6045298A patent/JPH06315437A/en active Pending

- 1994-03-16 CA CA002119178A patent/CA2119178A1/en not_active Abandoned

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB938617A (en) * | 1959-02-06 | 1963-10-02 | Sealpak Corp | Non-refillable infuser or container and method of using same |

| US3094917A (en) * | 1959-11-17 | 1963-06-25 | Koffie F Rombouts N V | Filtering device for the preparation of infusions, to be used only once |

| FR1347892A (en) * | 1962-11-23 | 1964-01-04 | Coffee filter | |

| FR2160634A1 (en) * | 1971-11-19 | 1973-06-29 | Marlet Barrera Jose |

Cited By (65)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5633026A (en) * | 1991-07-05 | 1997-05-27 | The Procter & Gamble Company | Tea filter pack for automatic brewers |

| US6139883A (en) * | 1995-07-29 | 2000-10-31 | J. R. Crompton Limited | Porous web material |

| US6548433B1 (en) | 1997-02-12 | 2003-04-15 | J. R. Compton Limited | Porous web material |

| US9862537B2 (en) | 2002-08-23 | 2018-01-09 | Koninklijke Douwe Egberts B.V. | Form-retaining pad for preparing a beverage suitable for consumption |

| USRE44759E1 (en) | 2002-08-23 | 2014-02-11 | Koninklijke Douwe Egberts B.V. | Form-retaining pad for preparing a beverage suitable for consumption |

| US8617627B2 (en) | 2002-08-23 | 2013-12-31 | Koninklijke Douwe Egberts B.V. | Form-retaining pad for preparing a beverage suitable for consumption |

| US8147886B2 (en) | 2002-08-23 | 2012-04-03 | Sara Lee/ De N.V. | Form-retaining pad for preparing a beverage suitable for consumption |

| EP1529739A1 (en) * | 2003-11-06 | 2005-05-11 | Keurig, Incorporated | Disposable beverage filter package |

| US9714136B2 (en) | 2004-04-28 | 2017-07-25 | Koninklijke Douwe Egberts B.V. | Pad and assembly of a holder and such a pad |

| US7832328B2 (en) | 2004-08-12 | 2010-11-16 | Sara Lee/De N.V. | System with a fluid path restriction for making a beverage |

| WO2006037062A1 (en) * | 2004-09-24 | 2006-04-06 | The Procter & Gamble Company | Liquid infusion pods containing insoluble materials |

| US8445047B2 (en) | 2005-10-14 | 2013-05-21 | Nestec S.A. | Apparatus for preparing a beverage from a capsule |

| US8039034B2 (en) | 2005-10-14 | 2011-10-18 | Nestec S.A. | Method for preparing a beverage from a capsule |

| US7981451B2 (en) | 2005-10-14 | 2011-07-19 | Nestec S.A. | Capsule for the preparation of a beverage |

| WO2007042415A1 (en) | 2005-10-14 | 2007-04-19 | Nestec S.A. | Method for preparing a beverage from a capsule |

| US8062682B2 (en) | 2005-11-10 | 2011-11-22 | Nestec S.A. | Beverage ingredient containing capsule having several compartments |

| ES2284388A1 (en) * | 2006-04-17 | 2007-11-01 | German Diaz Blanco | Disposable capsule for espresso machines |

| WO2007118914A1 (en) * | 2006-04-17 | 2007-10-25 | German Diaz Blanco | Single-use food-grade plastic or aluminium cup system with integral pressed ground coffee for placing in the cavity of an espresso coffee maker. |

| US9260238B2 (en) | 2006-08-10 | 2016-02-16 | Koninklijke Douwe Egberts B.V. | Method for providing a beverage provided with a fine-bubble froth layer or a beverage at least virtually without the fine bubble froth layer, pad with covering filled with product to be extracted and/or to be dissolved; assembly provided with such a pad and a holder; beverage preparation apparatus for preparing a beverage |

| US8163318B2 (en) | 2006-08-30 | 2012-04-24 | Nestec S.A. | Capsule for the preparation of a beverage |

| EP1894853A1 (en) | 2006-08-30 | 2008-03-05 | Nestec S.A. | Capsule for the preparation of a beverage |

| US8491948B2 (en) | 2006-08-30 | 2013-07-23 | Nestec S.A. | Capsule for the preparation of a beverage |

| EP1961676A3 (en) * | 2007-02-14 | 2009-07-29 | Arnoplast S.r.l. | Rigid capsule for coffee or other soluble products with improved lower seal |

| EP1961676A2 (en) | 2007-02-14 | 2008-08-27 | Arnoplast S.r.l. | Rigid capsule for coffee or other soluble products with improved lower seal |

| WO2008113779A3 (en) * | 2007-03-19 | 2009-05-07 | Nestec Sa | Capsule with flow regulating technology |

| EP1975087A3 (en) * | 2007-03-19 | 2008-10-08 | Nestec S.A. | Capsule with flow regulating technology |

| WO2008113779A2 (en) * | 2007-03-19 | 2008-09-25 | Nestec S.A. | Capsule with flow regulating technology |

| US8424447B2 (en) | 2007-03-19 | 2013-04-23 | Nestec S.A. | Capsule with flow regulating technology |

| EP2030915A3 (en) * | 2007-08-30 | 2009-09-16 | GVB Gesellschaft für Vermögensberatungen AG | Capsule and device for creating liquid food, in particular coffee |

| US20100303965A1 (en) * | 2007-09-03 | 2010-12-02 | Alain Mariller | Cartridge for preparing a beverage |

| US8850960B2 (en) | 2008-01-29 | 2014-10-07 | Koninklijke Douwe Egberts B.V. | System, method and capsule for preparing a beverage |

| US9725231B2 (en) | 2008-01-29 | 2017-08-08 | Koninklijke Douwe Egberts B.V. | System, method and capsule for preparing a beverage |

| WO2010126365A1 (en) * | 2009-04-27 | 2010-11-04 | Sara Lee/De N.V. | A pad for preparing a beverage, a container comprising several pads, an apparatus and a method for preparing the beverage |

| CN102459031B (en) * | 2009-05-29 | 2013-10-23 | 库里格股份有限公司 | Beverage cartridge with filter guard and manufacture method thereof as well as beverage system |

| CN102459031A (en) * | 2009-05-29 | 2012-05-16 | 库里格股份有限公司 | Beverage cartridge with filter guard |

| US20130129871A1 (en) * | 2010-05-20 | 2013-05-23 | Teatek Co., Ltd. | Beverage substance cartridge, water filling apparatus, beverage producing equipment, beverage producing system and beverage producing method |

| US9999316B2 (en) * | 2010-05-20 | 2018-06-19 | Teatek Co., Ltd. | Beverage substance cartridge, water filling apparatus, beverage producing equipment, beverage producing system and beverage producing method |

| US9932168B2 (en) | 2011-03-08 | 2018-04-03 | Kraft Foods R & D, Inc. | Beverage delivery pod and methods of use and manufacture |

| USD694620S1 (en) | 2011-03-08 | 2013-12-03 | Kraft Foods R&D, Inc. | Beverage cartridge |

| ES2398278A1 (en) * | 2012-08-28 | 2013-03-15 | Unión Tostadora, S.A. | Capsule for a beverage maker |

| WO2014033341A1 (en) * | 2012-08-28 | 2014-03-06 | Unión Tostadora, S.A. | Capsule for a beverage maker |

| TWI624414B (en) * | 2012-08-28 | 2018-05-21 | 庫克科技公司 | Capsule for beverage-making machines |

| USD708057S1 (en) | 2012-09-10 | 2014-07-01 | Kraft Foods R & D, Inc. | Beverage cartridge |

| US20140120217A1 (en) * | 2012-10-26 | 2014-05-01 | Printpack Illinois, Inc. | Container With Improved Puncture Design |

| WO2014066901A1 (en) * | 2012-10-26 | 2014-05-01 | Printpack Illinois, Inc. | Container with improved puncture design |

| US20140120218A1 (en) * | 2012-10-26 | 2014-05-01 | Printpack Illinois, Inc. | Container With Improved Puncture Design |

| WO2014110355A2 (en) * | 2013-01-11 | 2014-07-17 | Dlcr Acquisition, Llc | A beverage cartridge |

| WO2014110355A3 (en) * | 2013-01-11 | 2014-11-06 | Dlcr Acquisition, Llc | A beverage cartridge |

| US9783361B2 (en) | 2013-03-14 | 2017-10-10 | Starbucks Corporation | Stretchable beverage cartridges and methods |

| WO2014168940A3 (en) * | 2013-04-12 | 2014-12-04 | Printpack Illinois, Inc. | Containers and materials with improved punctureability |

| US9657155B2 (en) | 2013-04-12 | 2017-05-23 | Printpack Illinois, Inc. | Containers and materials with improved punctureability |

| US10099850B2 (en) | 2013-04-12 | 2018-10-16 | Printpack Illinois, Inc. | Containers and materials with improved punctureability |

| GB2513163A (en) * | 2013-04-18 | 2014-10-22 | British American Tobacco Co | Container |

| US11291237B2 (en) | 2013-04-18 | 2022-04-05 | British American Tobacco (Investments) Limited | Container comprising a first chamber and a second chamber |

| WO2015105412A1 (en) * | 2014-01-08 | 2015-07-16 | Koninklijke Douwe Egberts B.V. | Form retaining pad for use in a coffee maker |

| NL2012063C2 (en) * | 2014-01-08 | 2015-07-09 | Koninkl Douwe Egberts Bv | Form retaining pad for use in a coffee maker. |

| WO2015113758A1 (en) * | 2014-01-29 | 2015-08-06 | Espressocap S.P.A. | Pre-packaged pod of coffee powder |

| US20170101258A1 (en) * | 2014-03-11 | 2017-04-13 | Mars, Incorporated | Beverage preparation capsules |

| US10442610B2 (en) | 2014-03-11 | 2019-10-15 | Starbucks Corporation | Pod-based restrictors and methods |

| US10336531B2 (en) * | 2014-03-21 | 2019-07-02 | 2266170 Ontario Inc. | Capsule with steeping chamber |

| US10336498B2 (en) | 2014-06-10 | 2019-07-02 | Printpack Illinois, Inc. | Container with improved punctureability |

| US10820607B2 (en) | 2015-01-09 | 2020-11-03 | Starbucks Corporation | Soluble beverages with enhanced flavors and aromas |

| US9877495B2 (en) | 2015-01-09 | 2018-01-30 | Starbucks Corporation | Method of making a sweetened soluble beverage product |

| WO2018119390A1 (en) * | 2016-12-23 | 2018-06-28 | Ideators, LLC | Printable pattern filters |

| US10919691B2 (en) | 2018-04-05 | 2021-02-16 | Ideators, LLC | Beverage cartridge with needle puncture prevention |

Also Published As

| Publication number | Publication date |

|---|---|

| AU5649794A (en) | 1994-09-22 |

| JPH06315437A (en) | 1994-11-15 |

| CA2119178A1 (en) | 1994-09-18 |

| GB9305461D0 (en) | 1993-05-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0615921A1 (en) | Rigid cartridge for coffee or the like | |

| US4853234A (en) | Beverage packages | |

| US8127663B2 (en) | Apparatus for brewing and method for making the same | |

| US8667890B2 (en) | Cartridge for coffee and soluble products for preparing beverages | |

| EP0455337B1 (en) | Method of beverage preparation | |

| CN103271653B (en) | Use the method and system for preparing beverage or food liquid of brewing centrifugal force | |

| EP0615714A1 (en) | Apparatus and method for beverage preparation | |

| EP2651781B1 (en) | Capsule for beverage preparation | |

| EP2781174B1 (en) | Method, device and capsule for brewing a beverage | |

| EP1594763B1 (en) | A capsule to be used to prepare an infused beverage | |

| US5064980A (en) | Coffee maker | |

| US20040005384A1 (en) | Pod and method for making fluid comestible | |

| JPH034817A (en) | Beverage flavoring casette | |

| JPH05199938A (en) | Flexible cartridge type package | |

| CN104853996B (en) | The purposes of disposable pouring and boiling device and disposable pouring and boiling device | |

| EP2185043A1 (en) | Systems and methods of brewing low-cholesterol espresso | |

| US3483812A (en) | Coffee-filter | |

| JPH034816A (en) | Improved coffee casette | |

| WO1995001293A1 (en) | Tea filter pack for automatic brewers | |

| WO1991020170A1 (en) | Microwaveable coffee makers | |

| JPH04102932U (en) | coffee filter | |

| JPH0464686B2 (en) | ||

| JPH0271714A (en) | Green tea extractor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LI LU MC NL PT SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19950322 |