EP1340945B2 - Device for treating and preparing foodstuffs with gas combustion heating - Google Patents

Device for treating and preparing foodstuffs with gas combustion heating Download PDFInfo

- Publication number

- EP1340945B2 EP1340945B2 EP02004761A EP02004761A EP1340945B2 EP 1340945 B2 EP1340945 B2 EP 1340945B2 EP 02004761 A EP02004761 A EP 02004761A EP 02004761 A EP02004761 A EP 02004761A EP 1340945 B2 EP1340945 B2 EP 1340945B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- pipe

- cooking

- heat exchanger

- burner

- cooking chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000002485 combustion reaction Methods 0.000 title claims description 12

- 238000010438 heat treatment Methods 0.000 title description 3

- 238000010411 cooking Methods 0.000 claims description 30

- 239000000203 mixture Substances 0.000 claims description 10

- 239000007788 liquid Substances 0.000 claims description 2

- 238000009423 ventilation Methods 0.000 claims 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 11

- 238000010304 firing Methods 0.000 description 4

- 230000008020 evaporation Effects 0.000 description 2

- 238000001704 evaporation Methods 0.000 description 2

- 238000005452 bending Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/32—Arrangements of ducts for hot gases, e.g. in or around baking ovens

- F24C15/322—Arrangements of ducts for hot gases, e.g. in or around baking ovens with forced circulation

Definitions

- the present invention relates to a device for treating and preparing food, wherein the device is a cooking chamber, in which the food is treated or cooked, a motor-driven fan, which serves to circulate the cooking chamber prevailing in the cooking chamber, a burner for combustion of a Gas-air mixture is used, and has a heat exchange device having a heat exchanger tube means, which gives the fan to.

- a heat exchanger device for cooking appliances is for example from the DE 197 08 231 A1 known.

- the heat exchanger device of this prior art comprises a substantially horizontal combustion chamber, which is in communication with a heat exchanger tube into which the burned gas-air mixture is fed.

- the heat exchanger tube runs along the four sides of the cooking chamber in the direction away from the combustion chamber and reverses at the end of the fourth side by means of a cantilevered bending to again cover the same distance parallel to the pipe string leaving the combustion chamber.

- the only heat exchanger tube extends along the combustion chamber to below the cantilevered bend to dissipate the exhaust gas to the outside.

- a device for treating and preparing food namely a microwave oven

- the device has a housing with a cooking space in which the food is treated or cooked.

- the device has a motor-driven fan wheel, which serves to circulate the cooking chamber prevailing in the cooking chamber.

- a burner is provided which generates a flame for the combustion of the gas-air mixture during operation, wherein the burner is located outside the housing of the device and above it.

- the apparatus comprises a heat exchanger means having a heat exchanger tube means extending spirally in at least two surrounds around the impeller, wherein the flame generated during operation penetrates from above into the opening of the heat exchanger tube means.

- the heat exchanger tube means comprises two pipe strands which extend continuously substantially in a border or loop around the fan.

- the burner is located completely inside the housing and extends in the lower area of this only in the horizontal direction.

- the heat exchanger tube device extends the DE 298 00 523 U1 also in the vertical direction from top to bottom, so that the exhaust gas flow at the end of its path against its natural buoyancy direction must flow down.

- the present invention is therefore an object of the invention to provide a device for treating and preparing food with a cooking chamber, which is heated by gas firing, wherein the heat exchanger device provides a significantly improved heat transfer, which makes a significantly lower heating power possible, thereby significantly lower Exhaust losses occur.

- the three pipe strands are arranged triangularly in the tube longitudinal direction.

- the heat exchanger tubes additionally serve as a highly efficient evaporation device when, as provided in the present invention, water is injected via a feed line directly into the fan and transported from this to the outside becomes. Due to the radial spreading of the injected water, the water that has not yet evaporated on the outer circumference of the fan wheel is thrown onto the pipe strings and can finally evaporate there. This is advantageously also avoided that not yet evaporated water thrown to the cooking appliance inner wall.

- the pipe strands extend substantially along all four sides of the cooking chamber, but not along the burner. This will become one on the one hand realized a compact design of the cooking appliance and on the other hand increases the possible diameter of the Brennnerhunt, whereby a better and more complete combustion of the gas-air mixture is achieved.

- a flow profile is such that due to the friction of the gas at the pipe inner wall there is the lowest flow velocity and in the middle of the highest speed. This leads to a reduced heat exchanger performance, because the fast-flowing middle layer of the gas of a heat exchanger function can be little or no time spent.

- at least one pipe string preferably has all pipe strands at least one flow deflecting device. With the help of the flow deflecting device, the flowing gas can be converted from a laminar flow back into the turbulent flow, so that areas in the middle of the flow get out again and thus the efficiency of the heat exchange process is significantly increased.

- the advantage is also created that the length of the respective pipe string can be significantly shortened compared to the prior art.

- two flow diverters are spaced apart from one another in each tubing string so that multiple flow changes from a laminar flow to a turbulent flow to increase the efficiency of the heat exchanger are realized.

- the burner chamber is arranged substantially vertically, a particularly efficient combustion of the gas-air mixture is achieved, wherein the flame is directed downward in the burner chamber.

- This has the advantage that the hottest flow rate is introduced in the bottom of the cooking chamber, whereby a more uniform heat distribution is achieved in the oven.

- a guide of the exhaust gas is made possible so that the gas path in the device outside the cooking chamber can be kept as short as possible.

- FIG. 1 is shown schematically in side view, the structure of a device 1 according to the invention for treating and preparing food, in the form of a combi steamer having a housing 3.

- a cooking chamber 5 is provided, in which the food to be treated can be introduced.

- the cooking chamber 5 is closed at its front in a conventional manner with a door 7 and opened.

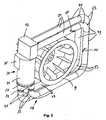

- FIG. 2 Behind a substantially vertically arranged the air baffle 25 is a radial fan 9, its construction clearly FIG. 2 is apparent.

- the radial fan 9 is driven by an asynchronous motor 11.

- the asynchronous motor 11 is arranged behind a rear wall 13 of the cooking chamber 5, and has a drive shaft 15 which is connected to the radial fan 9 for driving it.

- a supply air duct 17 is provided, in which a controllable flap 19 is arranged.

- a water inlet 21 is further provided which has a controllable inlet valve 23.

- the water inlet 21 ends in the central region of the fan 9, that is, the water to be evaporated is injected into the central region of the fan 9 and thrown radially outward due to the rotation of the fan 9, whereby already evaporates a portion of the water.

- the air guide plate 25 provided between the radial fan 9 and the cooking chamber 5 serves to distribute the air in the cooking chamber.

- a drain 27 is furthermore provided, via which liquid, in particular vapor, can drain off and which also serves to equalize the pressure.

- the heat exchanger device 29 extends around the radial fan 9 and follows substantially the inner contour of the cooking device 1.

- the heat exchanger device 29 is fed by a gas firing 31, which has a burner chamber 33.

- the burner chamber 33 is as out FIG. 2 visible, arranged vertically. It has a gas inlet 35, through which a gas-air mixture is introduced into the burner chamber 33.

- the pipe strands 41 extend in a border or loop around the impeller 9 and terminate in an exhaust collecting and dispensing device 43rd

- Each tubing string 41 has a substantially short first vertical tube section 45, a first substantially horizontal tube section 47, a second substantially vertical tube section 49 and a second substantially horizontal tube section.

- the pipe sections 45 to 51 are connected via pipe bend sections 53.

- the heat exchange gas moves in the tubing 41 before the flow deflector 55 substantially according to a flow profile 57.

- the laminar flow 57 is swirled, as indicated by the arrow 58.

- a uniform flow occurs, as indicated by the turbulent flow profile 59.

- FIG. 2 schematically only two flow deflection devices 55 are shown in the frontmost pipe string 41.

- at least two flow deflecting devices 55 are arranged in each of the pipe strands 41, wherein a further flow deflecting device 55 can be arranged in the first horizontal pipe section 47 and / or a further flow deflecting device 55 can be arranged in the second horizontal pipe section 51.

- FIG. 2 schematically illustrated embodiments of the flow deflecting device 55 in that the back pressure and thus the applied fan power can be minimized.

- the fan can be kept small, which probably promotes the compact design of the overall device and reduces the energy required for the operation of the fan.

- FIG. 1 In FIG. 1 is the triangular arrangement of the pipe strands 41 clearly visible.

- the ejected from the fan 9 in the radial direction of water strikes the pipe strands 41, wherein as from FIG. 1 As can be seen, these completely cover the radial application space of the fan.

- the ejected water strikes the pipe strands 41 and not on the inner wall 6 of the cooking appliance, whereby an optimal evaporation of the introduced water is achieved.

- FIG. 4 the gas firing 31 is shown schematically.

- a substantially circular grid 61 is arranged, and the gas-air mixture, which enters the burner chamber 33 via the gas inlet 35, flows through the grid 61.

- an ignition device 63 which is the gas-air mixture ignites and a dashed illustrated Brennkegel 65 is formed, which extends vertically downwards in the burner chamber 33.

- the arrangement of the flame cone 65 has the advantage of a substantially complete combustion of the gas-air mixture, wherein due to the grid, the flame cone 65 composed of a plurality of individual flames due to the lattice structure of the grid 61 composed.

- the present invention thus provides a device for treating and preparing foodstuffs with a gas firing system designed in a very advantageous manner and an advantageously designed heat exchanger device.

Description

Die vorliegende Erfindung betrifft ein Gerät zum Behandeln und Zubereiten von Nahrungsmitteln, wobei das Gerät einen Garraum, in dem die Nahrungsmittel behandelt bzw. gegart werden, ein motorgetriebenes Lüfterrad, das zur Umwälzung der im Garraum herrschenden Garraumatmosphäre dient, einen Brenner, der zur Verbrennung eines Gas-Luftgemisches dient, und eine Wärmetauschereinrichtung aufweist, die eine Wärmetauscherrohreinrichtung aufweist, die das Lüfterrad um gibt.The present invention relates to a device for treating and preparing food, wherein the device is a cooking chamber, in which the food is treated or cooked, a motor-driven fan, which serves to circulate the cooking chamber prevailing in the cooking chamber, a burner for combustion of a Gas-air mixture is used, and has a heat exchange device having a heat exchanger tube means, which gives the fan to.

Eine Wärmetauschereinrichtung für Gargeräte ist beispielsweise aus der

Ein besonderer Nachteil bei diesem Stand der Technik ergibt sich dadurch, daß einerseits ein sehr langer Weg des Heizgases in einem Wärmetauscherrohr benötigt wird, wodurch nur eine relativ schwache Wärmetauscherleistung verwirklicht wird, wobei strömungstechnisch der Verlauf des Wärmetauscherrohrs durch Umkehrung der Strömungsrichtung gemäß diesem Stand der Technik äußerst ungünstig ist.A particular disadvantage of this prior art results from the fact that on the one hand a very long way of the hot gas is required in a heat exchanger tube, whereby only a relatively weak heat exchanger performance is realized, wherein the flow of the course of the heat exchanger tube by reversal the flow direction according to this prior art is extremely unfavorable.

Aus der

Aus der

Der vorliegenden Erfindung liegt deshalb die Aufgabe zugrunde, ein Gerät zum Behandeln und Zubereiten von Nahrungsmitteln mit einem Garraum zu schaffen, welches durch Gasbefeuerung beheizt wird, bei dem die Wärmetauschereinrichtung eine erheblich verbesserte Wärmeübertragung liefert, was eine erheblich geringere Heizleistung möglich macht, wodurch erheblich geringere Abgasverluste entstehen.The present invention is therefore an object of the invention to provide a device for treating and preparing food with a cooking chamber, which is heated by gas firing, wherein the heat exchanger device provides a significantly improved heat transfer, which makes a significantly lower heating power possible, thereby significantly lower Exhaust losses occur.

Diese Aufgabe wird durch die Merkmale des Anspruchs 1 gelöstThis object is solved by the features of claim 1

Dadurch, daß die Wärmetauscherrohreinrichtung drei Rohrstränge aufweist, die sich kontinuierlich um das Lüftrad im wesentlichen in einer Umrandung des Lüfterrads erstrecken, wird erreicht, daß einerseits ein optimaler Strömungsweg für das Heizgas der Wärmetauscherrohreinrichtung geschaffen wird und zudem eine erheblich verbesserte Wärmetauscherfunktion erreicht wird, wobei die Wärmetauscherfunktion durch die drei Rohrstränge nach erhöht wird, d. h. der erhitzte Gasstrom wird in drei Teile aufgeteilt.Due to the fact that the heat exchanger tube device has three tube strands which extend continuously around the fan wheel essentially in a border of the fan, it is achieved that, on the one hand, an optimum flow path for the heating gas of the heat exchanger tube device is created and, in addition, a significantly improved heat exchanger function is achieved Heat exchanger function is increased by the three pipe strands, d. H. the heated gas stream is divided into three parts.

Weiterhin sind die drei Rohrstränge in Rohrlängsrichtung dreieckförmig angeordnet Dies hat den besonderen Vorteil, daß die Wärmetauscherrohre zusätzlich als höchst effiziente Verdampfungseinrichtung dienen, wenn, wie bei der vorliegenden Erfindung vorgesehen, Wasser über eine Zuführleitung direkt in das Lüfterrad eingespritzt wird und von diesem nach außen befördert wird. Durch die radiale Ausbringung des eingespritzten Wassers wird das am Außenumfang des Lüfterrads noch nicht verdampfte Wasser auf die Rohrstränge geschleudert und kann dort endgültig verdampfen. Damit wird vorteilhafterweise auch vermieden, daß noch nicht verdampftes Wasser an die Gargerätinnenwand geschleudert.Furthermore, the three pipe strands are arranged triangularly in the tube longitudinal direction This has the particular advantage that the heat exchanger tubes additionally serve as a highly efficient evaporation device when, as provided in the present invention, water is injected via a feed line directly into the fan and transported from this to the outside becomes. Due to the radial spreading of the injected water, the water that has not yet evaporated on the outer circumference of the fan wheel is thrown onto the pipe strings and can finally evaporate there. This is advantageously also avoided that not yet evaporated water thrown to the cooking appliance inner wall.

Vorteilhafterweise erstrecken sich die Rohrstränge im wesentlichen entlang aller vier Seiten des Garraums, jedoch nicht entlang des Brenners. Dadurch wird einer seits eine kompakte Bauweise des Gargeräts verwirklicht und andererseits der mögliche Durchmesser der Brennnerkammer erhöht, wodurch eine bessere und vollständigere Verbrennung des Gas-Luftgemisches erreicht wird.Advantageously, the pipe strands extend substantially along all four sides of the cooking chamber, but not along the burner. This will become one on the one hand realized a compact design of the cooking appliance and on the other hand increases the possible diameter of the Brennnerkammer, whereby a better and more complete combustion of the gas-air mixture is achieved.

Bei der Strömung eines Gases in einem Rohr stellt sich ein Strömungsprofil derart ein, daß aufgrund der Reibung des Gases an der Rohrinnenwand dort die geringste Strömungsgeschwindigkeit herrscht und in der Mitte die höchste Geschwindigkeit. Dies führt zu einer verminderten Wärmetauscherleistung, weil die schnell strömende mittlere Schicht des Gases einer Wärmetauscherfunktion nur wenig oder gar nicht zugebracht werden kann. Mit besonderem Vorteil weist wenigstens ein Rohrstrang bevorzugt alle Rohrstränge wenigstens eine Strömungsablenkeinrichtung auf. Mit Hilfe der Strömungsablenkeinrichtung kann das strömende Gas von einer laminaren Strömung wieder in die turbulente Strömung überführt werden, so daß Bereiche in der Mitte der Strömung wieder nach außen gelangen und damit der Wirkungsgrad des Wärmetauschsvorgangs deutlich erhöht wird. Zum anderen wird dadurch auch der Vorteil geschaffen, daß die Länge des jeweiligen Rohrstrangs gegenüber dem Stand der Technik erheblich verkürzt werden kann.In the flow of a gas in a pipe, a flow profile is such that due to the friction of the gas at the pipe inner wall there is the lowest flow velocity and in the middle of the highest speed. This leads to a reduced heat exchanger performance, because the fast-flowing middle layer of the gas of a heat exchanger function can be little or no time spent. With particular advantage, at least one pipe string preferably has all pipe strands at least one flow deflecting device. With the help of the flow deflecting device, the flowing gas can be converted from a laminar flow back into the turbulent flow, so that areas in the middle of the flow get out again and thus the efficiency of the heat exchange process is significantly increased. On the other hand, the advantage is also created that the length of the respective pipe string can be significantly shortened compared to the prior art.

Vorteilhafterweise sind in jedem Rohrstrang zwei Strömungsablenkeinrichtungen im Abstand voneinander angeordnet, so daß ein mehrfaches Verändern der Strömung von einer laminaren Strömung in eine turbulente Strömung zur Erhöhung des Wirkungsgrads des Wärmetauschers verwirklicht wird. Dadurch, daß die Brennerkammer im wesentlichen vertikal angeordnet ist, wird eine besonders effiziente Verbrennung des Gas-Luftgemischs erzielt, wobei die Flamme in der Brennerkammer nach unten gerichtet ist. Dies hat den Vorteil, daß die heißeste Strömungsmenge unten im Garraum eingeleitet wird, wodurch eine gleichmäßigere Wärmeverteilung im Garraum erreicht wird. Weiterhin ergibt sich der große Vorteil, daß eine Führung des Abgases dergestalt ermöglicht wird, daß der Gasweg im Gerät außerhalb des Garraums möglichst kurzgehalten werden kann.Advantageously, two flow diverters are spaced apart from one another in each tubing string so that multiple flow changes from a laminar flow to a turbulent flow to increase the efficiency of the heat exchanger are realized. Characterized in that the burner chamber is arranged substantially vertically, a particularly efficient combustion of the gas-air mixture is achieved, wherein the flame is directed downward in the burner chamber. This has the advantage that the hottest flow rate is introduced in the bottom of the cooking chamber, whereby a more uniform heat distribution is achieved in the oven. Furthermore, there is the great advantage that a guide of the exhaust gas is made possible so that the gas path in the device outside the cooking chamber can be kept as short as possible.

Weitere Einzelheiten, Merkmale und Vorteile der vorliegenden Erfindung ergeben sich aus der nachfolgenden Beschreibung unter Bezugnahme auf die Zeichnung. Darin zeigt:

- Fig. 1

- eine Seitenschnittansicht schematisch den Aufbau eines erfindungsgemäßen Geräts zum Behandeln und Zubereiten von Nahrungsmitteln in Form eines Kombidämpfers;

- Fig. 2

- in perspektivischer Ansicht die erfindungsgemäße Wärmetauschereinrichtung, die sich um das Radiallüfterrad erstreckt;

- Fig. 3

- eine schematische Darstellung eines Wärmetauscherrohres mit einer Strömungsablenkeinrichtung; und

- Fig. 4

- eine schematische Darstellung einer Brennerkammer mit dargestellter Flamme.

- Fig. 1

- a side sectional view schematically the structure of a device according to the invention for treating and preparing food in the form of a combi steamer;

- Fig. 2

- a perspective view of the heat exchanger device according to the invention, which extends around the radial fan;

- Fig. 3

- a schematic representation of a heat exchanger tube with a flow deflection device; and

- Fig. 4

- a schematic representation of a burner chamber with flame shown.

In

Hinter einem im wesentlichen vertikal angeordneten dem Luftleitblech 25 befindet sich ein Radiallüfter 9, dessen Aufbau deutlich aus

Zur Einstellung der Feuchte in dem Garraum 5 ist ein Zuluftkanal 17 vorgesehen, in dem eine steuerbare Klappe 19 angeordnet ist. Zur Erzeugung von Dampf im Garraum 5 ist weiterhin ein Wasserzulauf 21 vorgesehen, der ein steuerbares Zulaufventil 23 aufweist.To set the humidity in the cooking chamber 5, a supply air duct 17 is provided, in which a

Wie aus

Im unteren Bereich des Geräts 1 ist weiterhin ein Ablauf 27 vorgesehen, über den Flüssigkeit, insbesondere Wrasen ablaufen kann und der auch dem Druckausgleich dient.In the lower part of the device 1, a

Um das Radiallüfterrad 9 erstreckt sich eine Wärmetauschereinrichtung 29, die nachfolgend näher unter Bezugnahme auf

Wie aus

Am unteren Ausgang 37 der Brennerkammer 33 ist ein Wärmetauscheranschluß 39 vorgesehen, der in Verbindung steht mit drei Rohrsträngen 41, die die Wärmetauschereinrichtung 29 bilden.At the

Wie aus

Jeder Rohrstrang 41 weist einen im wesentlichen kurzen ersten vertikalen Rohrabschnitt 45, einen ersten im wesentlichen horizontalen Rohrabschnitt 47, einen zweiten im wesentlichen vertikalen Rohrabschnitt 49 und einen zweiten im wesentlichen horizontalen Rohrabschnitt auf. Die Rohrabschnitte 45 bis 51 sind über Rohrkrümmungsabschnitte 53 verbunden.Each

Wie aus

Wie aus

In

Ein besonderer Vorteil der vorliegenden Erfindung ergibt sich auch aus der in

In

In

Mit der vorliegenden Erfindung wird somit ein Gerät zum Behandeln und Zubereiten von Nahrungsmitteln mit sehr vorteilhaft ausgestalteter Gasbefeuerung und vorteilhaft ausgestalteter Wärmetauscheinrichtung geschaffen.The present invention thus provides a device for treating and preparing foodstuffs with a gas firing system designed in a very advantageous manner and an advantageously designed heat exchanger device.

Claims (4)

- An apparatus (1) for treating and preparing food, said apparatus comprising

a housing (3) comprising a cooking chamber (5), in which the food is treated and cooked,

a motor-driven ventilation fan (9), which serves for circulating the cooking chamber atmosphere which is present in the cooking chamber (5),

a burner (31) which for combusting a gas-air mixture provides a flame during operation and which is completely arranged within said housing (3), and

a heat exchange means (29), which comprises a heat exchange pipe means (41) which surrounds the ventilation fan (9),

characterized in

that said heat exchange pipe means comprises three pipe strands (41), which extend continuously substantially in one bordering or loop around the ventilation fan (9), and said three pipe strands (41) are arranged triangularly in the longitudinal direction of the pipe,

that said apparatus (1) comprises a lower part including an outlet (27) through which liquid, in particular expelled moisture can be discharged,

that the combustion chamber (33) of said burner (31) is arranged substantially vertically and is directed to the lower part of the apparatus (1), and in

that the flame (65) in said combustion chamber (33) during operation is arranged downwardly. - The cooking apparatus as claimed in claim 1, characterized in that the pipe strands (41) extend substantially along all four sides of the cooking chamber but not along the burner (31).

- The cooking apparatus as claimed in claim 1 or 2, characterized in that at least one flow deflection means (55) is arranged in at least one pipe strand (41).

- The cooking apparatus as claimed in claim 3, characterized in that in each pipe strand (41) two flow deflection means (55) are arranged in a distance to each other.

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE50208407T DE50208407D1 (en) | 2002-03-01 | 2002-03-01 | Apparatus for treating and preparing foodstuffs with gas-fired heating |

| DK02004761.9T DK1340945T4 (en) | 2002-03-01 | 2002-03-01 | Apparatus for the processing and preparation of food with gas-fired heating and heat exchanger device for such apparatus |

| EP02004761A EP1340945B2 (en) | 2002-03-01 | 2002-03-01 | Device for treating and preparing foodstuffs with gas combustion heating |

| US10/375,382 US7325480B2 (en) | 2002-03-01 | 2003-02-27 | Apparatus for treating and preparing food by gas-fired heating and a heat exchange device for such an apparatus |

| JP2003054629A JP2003262339A (en) | 2002-03-01 | 2003-02-28 | Apparatus for treating and preparing food by gas combustion heating and heat exchanger means for such apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP02004761A EP1340945B2 (en) | 2002-03-01 | 2002-03-01 | Device for treating and preparing foodstuffs with gas combustion heating |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1340945A1 EP1340945A1 (en) | 2003-09-03 |

| EP1340945B1 EP1340945B1 (en) | 2006-10-11 |

| EP1340945B2 true EP1340945B2 (en) | 2009-08-26 |

Family

ID=27675677

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02004761A Expired - Lifetime EP1340945B2 (en) | 2002-03-01 | 2002-03-01 | Device for treating and preparing foodstuffs with gas combustion heating |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7325480B2 (en) |

| EP (1) | EP1340945B2 (en) |

| JP (1) | JP2003262339A (en) |

| DE (1) | DE50208407D1 (en) |

| DK (1) | DK1340945T4 (en) |

Families Citing this family (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DK1340945T4 (en) * | 2002-03-01 | 2010-01-25 | Eloma Gmbh Innovative Koch Und | Apparatus for the processing and preparation of food with gas-fired heating and heat exchanger device for such apparatus |

| DE202004016446U1 (en) * | 2004-10-23 | 2006-03-23 | Wss Gmbh | Heat exchanger unit for gas-heated devices for heat treatment of foodstuffs has partitions in combustion chamber to form unsealed communicating chambers to correspond to heat exchanger tubes connected to combustion chamber |

| CN103329951A (en) | 2008-01-28 | 2013-10-02 | 杜克制造公司 | Convection oven |

| DE202008010227U1 (en) | 2008-07-31 | 2009-12-10 | Klouda, Jaroslav, Dipl.-Ing. | Gas premix burner and heat exchanger system for cooking, cooking and other thermal appliances |

| IT1392974B1 (en) * | 2009-02-17 | 2012-04-02 | Premark Feg Llc | HEAT EXCHANGER FOR A PROCESSING DEVICE FOR FOOD AND OVEN PROVIDED |

| IT1402171B1 (en) * | 2010-07-21 | 2013-08-28 | Premark Feg Llc | FOOD PROCESSING DEVICE, IN PARTICULAR OVEN, PROVIDED WITH A IMPROVED HEAT EXCHANGER |

| EP2420744A1 (en) * | 2010-08-18 | 2012-02-22 | Eloma GmbH | Gas heat exchanger for devices for processing food and such a device |

| KR101278621B1 (en) | 2011-12-13 | 2013-07-05 | 이노엔 주식회사 | Heat exchanger for cooking apparatus |

| KR101381561B1 (en) * | 2012-10-26 | 2014-04-04 | 린나이코리아 주식회사 | Heat exchange device and convection oven with the same |

| KR101370415B1 (en) * | 2012-10-29 | 2014-03-06 | 린나이코리아 주식회사 | Slant disposition type heat exchange device and convection oven with the same |

| KR101381562B1 (en) * | 2012-10-31 | 2014-04-04 | 린나이코리아 주식회사 | Ellipse section type heat exchange device and convection oven with the same |

| KR101428870B1 (en) * | 2012-11-27 | 2014-08-14 | 엘지전자 주식회사 | Gas oven range |

| US9372005B2 (en) | 2012-11-30 | 2016-06-21 | Alto-Shaam, Inc. | Heat exchanger for oven |

| JP6198089B2 (en) * | 2013-06-07 | 2017-09-20 | イノエン インコーポレイテッド | Heat exchanger for cooking equipment |

| KR101564505B1 (en) * | 2014-04-03 | 2015-10-29 | 엘지전자 주식회사 | Cooking appliance |

| USD762289S1 (en) * | 2014-07-15 | 2016-07-26 | Dometic Sweden Ab | Heat exchanger |

| KR101663888B1 (en) | 2015-02-13 | 2016-10-14 | 엘지전자 주식회사 | Cooking device |

| USD787041S1 (en) | 2015-09-17 | 2017-05-16 | Whirlpool Corporation | Gas burner |

| US10837651B2 (en) | 2015-09-24 | 2020-11-17 | Whirlpool Corporation | Oven cavity connector for operating power accessory trays for cooking appliance |

| KR101721832B1 (en) * | 2015-11-23 | 2017-03-31 | 인하대학교 산학협력단 | Oven heat exchanger |

| US11777190B2 (en) | 2015-12-29 | 2023-10-03 | Whirlpool Corporation | Appliance including an antenna using a portion of appliance as a ground plane |

| US10145568B2 (en) | 2016-06-27 | 2018-12-04 | Whirlpool Corporation | High efficiency high power inner flame burner |

| KR101742185B1 (en) | 2016-10-25 | 2017-05-30 | 주식회사 효신테크 | The heat exchanger |

| US10551056B2 (en) | 2017-02-23 | 2020-02-04 | Whirlpool Corporation | Burner base |

| US10451290B2 (en) | 2017-03-07 | 2019-10-22 | Whirlpool Corporation | Forced convection steam assembly |

| US10660162B2 (en) | 2017-03-16 | 2020-05-19 | Whirlpool Corporation | Power delivery system for an induction cooktop with multi-output inverters |

| CN107216887B (en) * | 2017-06-26 | 2023-08-04 | 中冶华天工程技术有限公司 | Coke oven raw gas rising pipe heat exchanger |

| US10627116B2 (en) | 2018-06-26 | 2020-04-21 | Whirlpool Corporation | Ventilation system for cooking appliance |

| US10619862B2 (en) | 2018-06-28 | 2020-04-14 | Whirlpool Corporation | Frontal cooling towers for a ventilation system of a cooking appliance |

| US10837652B2 (en) | 2018-07-18 | 2020-11-17 | Whirlpool Corporation | Appliance secondary door |

| CN110715520A (en) * | 2019-09-09 | 2020-01-21 | 陈国� | Environment-friendly and energy-saving drying device |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5556566A (en) † | 1994-06-22 | 1996-09-17 | Zanussi Grandi Impianti S.P.A. | Combined gas-microwave cooking oven with steam operation |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3889099A (en) * | 1974-07-31 | 1975-06-10 | Gen Electric | Door cooling system |

| US4110916A (en) * | 1976-08-30 | 1978-09-05 | Bemrose Harold E | Forced air food drier |

| US5215000A (en) * | 1988-03-29 | 1993-06-01 | A.R.M.I.N.E.S. | Method and apparatus for thermal treatment of alimentary substances |

| FR2650061B1 (en) * | 1989-07-19 | 1991-11-15 | Gaz De France | IMPROVED OVEN OPERATING ON STEAM AND / OR GAS |

| DE4125696C1 (en) * | 1991-08-02 | 1993-02-18 | Eloma Gmbh Grosskuechentechnik, 8031 Maisach, De | Steam cooker with air fan wheel - vaporises water before reaching heaters with water inlets controlled by valves |

| IT1253697B (en) * | 1991-08-05 | 1995-08-22 | Zanussi Grandi Impianti Spa | FORCED CONVECTION GAS COOKING OVEN. |

| IT231984Y1 (en) * | 1993-11-15 | 1999-08-10 | Zanussi Grandi Impianti Spa | COOKING OVEN EQUIPPED WITH A PERFECTED STEAM CONTROL DEVICE |

| FR2728656B1 (en) * | 1994-12-21 | 2000-02-18 | Fagor S Coop Ltda | COMMERCIAL GAS COOKING OVEN |

| DE29800523U1 (en) | 1998-01-14 | 1999-05-12 | Greuel Peter | Convection oven |

| DE19824172A1 (en) * | 1998-05-29 | 1999-12-09 | Rational Gmbh | Cooking appliance with energy storage and energy extraction system |

| IT1311159B1 (en) * | 1999-11-30 | 2002-03-04 | Angelo Grandi Cucine Spa | HEAT EXCHANGER DEVICE FOR OVENS USED FOR DIAL COOKING |

| NL1014044C2 (en) * | 2000-01-10 | 2001-07-19 | Levens Group B V | Oven heated by gas burner. |

| IT1315481B1 (en) * | 2000-07-25 | 2003-02-18 | Gierre Srl | FORCED CONVECTION OVEN FOR COOKING FOOD |

| DK1340945T4 (en) * | 2002-03-01 | 2010-01-25 | Eloma Gmbh Innovative Koch Und | Apparatus for the processing and preparation of food with gas-fired heating and heat exchanger device for such apparatus |

| DK1342414T3 (en) * | 2002-03-07 | 2006-10-02 | Eloma Gmbh | Method of measuring humidity in an apparatus for processing and preparing food as well as apparatus for processing and preparing food |

-

2002

- 2002-03-01 DK DK02004761.9T patent/DK1340945T4/en active

- 2002-03-01 DE DE50208407T patent/DE50208407D1/en not_active Expired - Lifetime

- 2002-03-01 EP EP02004761A patent/EP1340945B2/en not_active Expired - Lifetime

-

2003

- 2003-02-27 US US10/375,382 patent/US7325480B2/en not_active Expired - Fee Related

- 2003-02-28 JP JP2003054629A patent/JP2003262339A/en active Pending

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5556566A (en) † | 1994-06-22 | 1996-09-17 | Zanussi Grandi Impianti S.P.A. | Combined gas-microwave cooking oven with steam operation |

Also Published As

| Publication number | Publication date |

|---|---|

| US7325480B2 (en) | 2008-02-05 |

| EP1340945B1 (en) | 2006-10-11 |

| JP2003262339A (en) | 2003-09-19 |

| DE50208407D1 (en) | 2006-11-23 |

| US20030164096A1 (en) | 2003-09-04 |

| DK1340945T3 (en) | 2007-02-19 |

| DK1340945T4 (en) | 2010-01-25 |

| EP1340945A1 (en) | 2003-09-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1340945B2 (en) | Device for treating and preparing foodstuffs with gas combustion heating | |

| DE60018118T2 (en) | COMBINED OVEN WITH THREE-STAGE WATER DRAINER | |

| DE724998C (en) | Pressure exchanger, e.g. B. for refrigeration machines | |

| DE60027482T2 (en) | METHOD AND DEVICE FOR GENERATING CONVECTION ENERGY | |

| DE1802196A1 (en) | Burner unit for radiator | |

| DE1426648B2 (en) | Rapid steam generator | |

| DE60018251T2 (en) | Heat exchanger for food oven. | |

| DE1778150A1 (en) | Gas heater | |

| DE3602285A1 (en) | WARM FURNACE FOR SOLID FUELS | |

| EP1010384B1 (en) | Cooking apparatus and method for heat treatment of a cooking product with steam | |

| DE102009043806B4 (en) | Rack Oven | |

| DE2533855A1 (en) | HEATER FOR LIQUID | |

| EP0128463A2 (en) | Space heating apparatus for small spaces | |

| EP1321720A1 (en) | Heat exchange arrangement | |

| DE857684C (en) | Boiler with a combustion chamber surrounded by a water jacket | |

| DE2508727A1 (en) | Heat exchanger with centrifugal blower - has ring of thermally conductive guide blades connected with thermal conductors | |

| EP0406173B1 (en) | Boiler | |

| DE2943590A1 (en) | METHOD FOR FIRING A BOILER AND BOILER FOR CARRYING OUT THE METHOD | |

| DE3428330A1 (en) | Baking oven | |

| DE10220624A1 (en) | Combi-type oven for commercial use e.g. restaurants, has opening area that leads to baking chamber, to collect steam on their way towards exterior of oven | |

| DE60002592T2 (en) | GAS DETECTOR, ESPECIALLY FOR RUBBER PRODUCTS | |

| DE10121415B4 (en) | Rack Oven | |

| EP2551603A2 (en) | Hall heating with calorific technology | |

| EP2661585B1 (en) | Burner arrangement for a mobile heatable device, in particular for a mobile cooking device | |

| DE19948876C2 (en) | Process for creating a homogeneous air flow in a forced draft burner and device for its implementation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17P | Request for examination filed |

Effective date: 20040217 |

|

| AKX | Designation fees paid |

Designated state(s): BE DE DK IT NL |

|

| 17Q | First examination report despatched |

Effective date: 20050311 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: DEVICE FOR TREATING AND PREPARING FOODSTUFFS WITH GAS COMBUSTION HEATING |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ELOMA GMBH - INNOVATIVE KOCH- UND BACKTECHNIK |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE DK IT NL |

|

| REF | Corresponds to: |

Ref document number: 50208407 Country of ref document: DE Date of ref document: 20061123 Kind code of ref document: P |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: ANGELO PO GRANDI CUCINE S.P.A. Effective date: 20070710 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: ANGELO PO GRANDI CUCINE S.P.A. |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PLBP | Opposition withdrawn |

Free format text: ORIGINAL CODE: 0009264 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20090826 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): BE DE DK IT NL |

|

| NLR2 | Nl: decision of opposition |

Effective date: 20090826 |

|

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T4 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50208407 Country of ref document: DE Representative=s name: VON LIERES BRACHMANN SCHULZE PATENTANWAELTE, DE Ref country code: DE Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20140320 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20140320 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20150401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20200325 Year of fee payment: 19 Ref country code: DK Payment date: 20200323 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20200327 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50208407 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20210331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210301 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210331 |