WO1990011572A1 - Integrated electronic parts warehousing and distribution system and method - Google Patents

Integrated electronic parts warehousing and distribution system and method Download PDFInfo

- Publication number

- WO1990011572A1 WO1990011572A1 PCT/US1990/001485 US9001485W WO9011572A1 WO 1990011572 A1 WO1990011572 A1 WO 1990011572A1 US 9001485 W US9001485 W US 9001485W WO 9011572 A1 WO9011572 A1 WO 9011572A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- computer

- buyer

- order

- item

- vendor

- Prior art date

Links

Classifications

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/08—Logistics, e.g. warehousing, loading or distribution; Inventory or stock management

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G1/00—Storing articles, individually or in orderly arrangement, in warehouses or magazines

- B65G1/02—Storage devices

- B65G1/04—Storage devices mechanical

- B65G1/137—Storage devices mechanical with arrangements or automatic control means for selecting which articles are to be removed

- B65G1/1373—Storage devices mechanical with arrangements or automatic control means for selecting which articles are to be removed for fulfilling orders in warehouses

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/08—Logistics, e.g. warehousing, loading or distribution; Inventory or stock management

- G06Q10/087—Inventory or stock management, e.g. order filling, procurement or balancing against orders

-

- G—PHYSICS

- G07—CHECKING-DEVICES

- G07F—COIN-FREED OR LIKE APPARATUS

- G07F7/00—Mechanisms actuated by objects other than coins to free or to actuate vending, hiring, coin or paper currency dispensing or refunding apparatus

-

- G—PHYSICS

- G07—CHECKING-DEVICES

- G07G—REGISTERING THE RECEIPT OF CASH, VALUABLES, OR TOKENS

- G07G1/00—Cash registers

Definitions

- This invention relates to warehousing and distribution systems and methods, and particularly to such systems and methods for warehousing and distributing

- a buyer wishes to purchase a specific item. If the buyer has a source book which lists multiple suppliers of a variety of items, he can look up the names of more than one supplier. Further, if the buyer has obtained catalogs from any of those suppliers, he can look up the item to obtain price and delivery

- the source book itself also causes additional problems. First, it usually is revised only infrequently and thus often is out of date. Additionally, the source book lists suppliers who may no longer handle the item, or may handle it only as a convenience to their customers and do not maintain it in stock. This means that they probably cannot provide fast delivery and that their prices will most likely be considerably higher than others. Further, the suppliers may no longer be at the listed location or even in business. Attempting to call or write to any of the above suppliers, clearly wastes a large amount of a buyer's time.

- a buyer wishing to place an order usually must prepare a written purchase order and mail it to the supplier.

- the supplier typically acknowledges the order in writing, giving expected shipping dates, and other pertinent information. Of course, the supplier also can refuse the order. All of this written communication can go on for days or even weeks.

- Orders can also be given by telephone. This can be a much faster system if the proper person can be reached at the supplier's place of business. However, this approach is less than fully satisfactory because it increases the chances for error in that spoken words are frequently not reduced to writing for visual verification. Even if the order is reduced to writing, it easily can be written incorrectly, thus creating an incorrect order.

- Still other errors may be caused by differences in nomenclature and specifications for particular items.

- Many suppliers have their own names and part numbers for specific items. Both the deviation in name and part number can cause numerous errors since each usually must be looked up and verified for each different supplier. This not only creates an additional source of errors, but takes still further time.

- it is often most cost- efficient to consolidate those orders with one or a small number of suppliers. Typically, the selection of the suppliers is made haphazardly and the lowest total price is often not obtained.

- Such a system did not provide any means for identifying multiple vendors for a given item, or for operating other than on a contract basis. Thus, the buyer could not quickly shop for the best price or terms from a variety of vendors.

- Yet another system collects information from suppliers concerning their surplus inventory.

- Another system which was proposed had suppliers or vendors listing their items on a central computer, along with their current price schedule. Buyers who subscribed to the system were to be able to access the central computer which would display on a computer screen the particular item and the various suppliers offering that item along with the current prices. When a supplier wished to place an order he could prepare an electronic purchase order which would be sent via the central computer to the vendor's terminal. The vendor could then respond any time after receiving the order with either a confirmation, change of price, or rejection. Further, this system still required the vendor to accept or reject the order and to ship the products from his location. Such a system still failed to optimize the ordering and shipping procedures.

- the manufacturer's telephone salesperson usually are trained by quote prices for large production orders, for which they may receive a significant commission. They may consider the process of quoting price and availability for small stock quantities to be a waste of time, especially if they receive many inquiries but few orders.

- the warehouse may not be geared to ship small quantities of an item, nor to make some day shipments when requested. Therefore, the smaller orders are lost, and with them the larger follow-on orders which can be so valuable.

- the manufacturer may run out of stock on active items, thereby generating more non-productive inquiries.

- distributor may refuse to carry the product at all.

- the overseas manufacturer also has special problems. Currently, an overseas manufacturer has roughly three options for selling his products in the U.S.

- manufacturer's own direct sales staff In many cases, the customer does not know the name of the manufacturer, and for repeat orders, the customer may move to another manufacturer if he receives a lower price or quicker delivery. Thus, the manufacturer loses follow-up business, and often must suffer with extremely modest profit margins.

- a second option for the foreign manufacturer is to place a consignment inventory at one or more stocking distributors in the U.S. This has the advantage of opening the market to more customers, but the manufacturer is limited to the sales and marketing scope of these

- distributors simply may not be reaching anywhere near the full potential market for the product. If there is only one distributor, there is only limited coverage, while with more than one distributor, the inventory investment is multiplied, while the incentive for the distributors to sell the product is reduced. The cost for this service may be high, and this may make the price of the product non- competitive.

- a third option is for the foreign manufacturer to open his own warehouse in the U.S. This is probably the most costly option of all. The manufacturer must pay for the purchase or rental of a warehouse, buy or rent a full range of warehouse equipment, staff the warehouse and office operations, and still have to pay for a full sales and marketing efforts, he probably can reach only a small portion of the potential customers.

- the system and method allow the buyer to quickly obtain the name of at least one vendor, and preferably a substantial list of vendors, for any one of a large quantity of different items. Moreover, the buyer is provided, at the same time, with the prices charged by each vendor for the item and the

- the physical items are stored in a central public warehouse containing products owned by many different business entities.

- the information communicated to the buyer is for the items in that warehouse.

- system and method provide electronic communication between the buyer and a central computer which maintains a running inventory of the public warehouse system as well as additional pertinent information including suppliers' names, business history, prices and re-supply schedule.

- the buyer can inquire as to the availability and pricing of a multitude of items maintained by the central public warehouse system by inputting part numbers into a local input/output (“I/O") device and

- the central computer electronically communicating those parts numbers to the central computer, in a batch.

- the central computer then provides a list of vendors who maintain an inventory of the particular item within the public warehouse system, the price of the part charged by each vendor and the quantity of that item in stock and available from the public warehouse system.

- the buyer can create a purchase order on his I/O device, which is then electronically transmitted to the central computer. This, order is then conveyed to the public warehouse system by the central computer for processing.

- the central public warehouse system electronically communicates with the central computer to maintain a running inventory of the items stored in the warehouse system. This communication also is used to provide a comprehensive warehouse control system which not only directs and

- Data is maintained by the central computer on the frequency of inquiry of buyers for each particular part stocked by a vendor, orders placed, etc. Suppliers can electronically obtain this data by communicating with the central computer through an I/O device.

- the buyer maintain a letter of credit with a pre-designated bank such that sometime after the transmittal of an electronic purchase order to the central computer the necessary funds may be wire-transferred through the pre-designated bank to the vendor.

- a central computer which is the same computer as that which is used to accept inquiries and orders from buyers, is used to assign random storage locations in each of the three full container storage areas. This assignment is done as shipments are received in the warehouse. At the time shipments are received, computer generated labels as well as bar codes are placed on each incoming container.

- the labels provide a variety of information about each container including its intended storage location, supplier, part number, etc.

- the bar code is used strictly to identify each container. This bar code information is stored in a local warehouse computer (PC) along with the label

- the computer system directs the movement of the containers in the warehouse.

- the central computer In response to orders which have been input to the central computer by buyers (and sometimes by vendors) the central computer generates

- containers of the items are moved around in the warehouse from each of the four storage areas.

- the movement is accompanied by a newly generated computer label which includes the new storage location or customer information as well as the other information which was recorded at the time of the container's receipt.

- the container's bar code is also scanned to verify that the proper container is being moved.

- various documentation which has been generated by the computer in accordance with the order and the information stored upon receipt, is reviewed. This is the final check of the order before it leaves the warehouse and is accompanied by a complete scan of each individual container's barcode. Thus, the integrity of the order is verified.

- PCs local microcomputers

- the public warehouse system permits specialization in a given market.

- all the suppliers to the warehouse system are concentrated in a single industry, with a clearly defined customer base, it is possible to provide more options than would be available otherwise.

- buyers can access the warehouse system's composite inventory database to obtain instant quotations and place orders for immediate shipments based on current inventory. This can be done despite the fact that items may be from several different suppliers. In most previous systems, the buyer's computer access was limited to a single supplier.

- Paper work is also minimized since no actual purchase orders are sent. Lead time is cut down since the order need not be called back in by the buyer to a chosen supplier and can be shipped almost immediately.

- the order is transmitted electronically to the central computer used by the warehouse system and can thus be filled right away. The order is further expedited since the items are

- the buyer also has the ability to enter reservations instead of placing conventional backorders with a single supplier.

- the warehouse operating efficiently because of the two or four storage area system is capable of shipping many orders with minimal labor costs.

- the supplier likewise saves money and gains other advantages with the present system and method. He can minimize his warehousing costs by wholly or partially maintaining his inventory in the warehouse system. Still further, the supplier can dramatically cut down on the number of inquiries he handles. He can save still more because his paper work in processing orders and bills is greatly reduced for all items maintained in the warehouse system.

- a supplier also has access to a client base that may never contact him otherwise. Once a buyer places an inquiry for a part which the supplier maintains in the warehouse system, the buyer must see the supplier's offering regardless of his intention. This then, gives the supplier considerably more exposure than would be possible in a normal trading environment. Since there is no need for a buyer to make phone calls to specific suppliers, the

- the electronic funds transfer system virtually guarantees payments to the supplier and maximizes both the supplier's and buyer's use of the funds.

- FIG. 1 is a schematic diagram of an ordering system constructed in accordance with the present invention

- Figure 2 is a flow chart illustrating the computer program and operating steps taken by the user in using the system as a buyer;

- Figures 3-5 are further flow chart diagrams illustrating detailed features of the flow chart of Figure 2;

- Figure 6 is a flow chart illustrating the operative steps of the billing procedure of the ordering system of the present invention.

- Figure 7 is a warehouse layout in accordance with one embodiment of the warehouse system of the present invention.

- Figure 8 is a warehouse layout in accordance with a second embodiment of the warehouse system of the present invention.

- FIG 1 illustrates schematically a portion 30 of the system of the invention.

- the system portion 30 includes central data processing equipment at a first station 32 in the warehouse ( Figures 7 and 8), and two separate sets of input/output equipment at two other stations 34 and 36 each of which is labelled "Buyer or Vendor" in Figure 1. Since the equipment of each of stations 34 and 36 is essentially identical, except for programming, the equipment at either station can be used either by buyers or sellers, or simply for communications purposes.

- the central processing station 32 is located at the public warehouse, and each of the remote stations 34 and 36 is located at the offices of a different business concern.

- a warehousing firm owns and operates the warehouse, and makes its data processing equipment and services available to the others.

- the central data processing equipment located at the warehouse includes a computer CPU 38.

- the computer preferably is a moderately high-speed, high-capacity

- the computer such as a minicomputer; the computer can be any general purpose digital computer having a sufficient speed and capacity for processing data in the system.

- an input/output device 40 comprising a keyboard and screen, which is used for programming purposes, a set of disk files 42, and input tape file 44, an output tape file 46, a printer 48, and a modem 56.

- the input tape file 44 includes means for reading into computer memory data supplied on magnetic tape by buyers and vendors to be stored in the system.

- the disk files 42 are used for data storage, along with the RAM memory in the computer itself.

- the tape file 46 is used to read out data accumulated for buyers and vendors and supplying that data to the printer 48 which is used to print out reports to be sent to the buyers and vendors at periodic intervals.

- the modem 56 is used for sending and receiving data over telephone lines 56, 58 and 60 to the modems 54 of the various vendor and buyer terminals.

- the equipment at each of the vendor and buyer terminals includes a computer unit 50 including a keyboard disk file and video display screen, and a printer 52.

- the computer 50 can be any suitable small computer such as the IBM Personal Computer or any equivalent machine.

- the computer 50 hs RAM storage as well as disk storage.

- each of the computers 50 incorporate a color display. This tends to enhance the rapid identification of different items of information which appear on the screen.

- the preferred embodiment of the invention operates, in general, as follows.

- Each vendor rents space in the warehouse, or pays a storage fee based on the number and size of the containers in the warehouse at a given time.

- the vendor thus, stores an inventory of his products in the warehouse space and provides a list of prices for these products.

- the computer 38 displays on the screen of the buyer's terminal 50 a list of vendors which maintain an inventory of the item in the warehouse, the item, the price for the specific quantity desired by the buyer and the inventory and price level for the item.

- the computer 38 maintains inventory information for the items in the warehouse.

- the buyer sends his order electronically to the central computer 38 which prepares the necessary paperwork for the rapid and efficient picking, packing and shipping of the order from the public warehouse.

- a single warehouse system is provided for storing items manufactured or sold by a number of different

- the items stored in the system are all owned by the supplier or vendor who provides them. They are not owned by the warehouse system proprietors.

- the warehouse system comprises one or more

- warehouses each having storage racks, conveyors, scales and other typical warehouse fixtures. All the warehouses are linked together by the central computer 38 ( Figure 1) to create a single warehouse system.

- the central computer 38 directs the movement of all items in the warehouse.

- the central computer 38 also receives orders in accordance with the procedure and system described above. These orders are filled through the warehouse system in accordance with directions from the central computer 38.

- warehouse system for storage purposes may be manufacturers as well as distributors) are obligated to maintain their own inventory levels in the warehouse system. While the central computer 38 can indicate restocking points and generally low inventory levels, the supplier restocks at his own

- a supplier or vendor sends particular items, or his entire inventory to be maintained in the single warehouse system. It remains entirely at the supplier's discretion which items are maintained by the warehouse system and at which warehouse location.

- a supplier ships its products to the warehouse system

- the supplier or vendor can then monitor the status of its products in the warehouse system. Even while his products remain in the warehouse system the supplier

- This system permits a supplier to either eliminate his warehouse entirely or simply pass on fast moving items which are sold in smaller quantities. Even though the supplier maintains ownership of the products he is no longer responsible for preparing quotations or processing purchase orders and bills. The supplier still maintains complete control over the selling prices and can set different discounts or adders for individual customers.

- Figure 2 is the buyer flow chart which illustrates the step followed by the buyer and the computer 50 at the buyer's terminal 34 or 36.

- the start up of the computer 50 (see Figure 1) at the buyer station 34 or 36 is indicated at 62 in Figure 2.

- the computer 50 (preferably a personal computer like the IBM PS/2 Model 50) is programmed to provide a routine, indicated at 64, in which the operator enters a password and/or an account number for the company by which he is employed, as indicated at 66.

- the computer 50 decides, as indicated at 68, whether the password and account number are valid. If not, the routine is ended as indicated at 70. If they are valid, the computer displays a menu screen as indicated at 72.

- Each of the tables which is set forth in the following text is a reproduction of the information which appears on the screen of a video monitor at a buyer, vendor or warehouse station.

- this selection process is indicated at 74. It usually will be made by using one or more key strokes on the keyboard of the computer 50 at the buyer station 36. Alternatively, the selection can be made, if the screen of the computer is of the "touch-screen” variety by merely touching the number of the option

- the buyer is usually a distributor who is buying products to fill an order from one of his customers.

- the operator may begin by designating a customer in connection with this inquiry. If he wants to store the inquiry for later recall, and limit the matches only to this customer, then this entry is mandatory.

- These customer account records may be stored in a file in the buyer's computer 50 and will never be sent to the central computer 38. This ensures the confidentiality of the identity of the buyer's customers.

- the operator can enter the customer account code or the customer telephone number. If he wishes, he can enter a few letters of the customer name, and a listing of accounts starting at that point will be displayed so he can choose the desired account.

- the operator must enter an item or part number as indicated at 76 in Figure 3.

- the item number can be, for example, military part numbers or similar part numbers selected to facilitate the alpha-numeric identification of a substantial number of fasteners, electronic components or other small parts.

- the part numbers are the same for all users of the system. If the operator is entering a part number for a generic type of fastener, the part number can be generated by a series of table lookups. If this option is accepted, the full description of the part can be displayed for verification on the line below the item number.

- Items may be identified by more than one part number.

- the system also offers the buyer a table of

- interchangeable part numbers so that the buyer may enter any of the applicable part numbers and will be assured of getting the correct part.

- the system permits the buyer to enter substitute part numbers for items that are slightly different from the basic part number. These substantive parts may be offered only on quotations when there is an insufficient quantity of the basic part in inventory.

- the buyer may also activate, a history recall module if desired.

- This module can be set to display matching items for any customer, or only this customer. If activated, any inquiry or quotation that was previously stored in the buyer's computer will be displayed immediately after the item is entered. This step also is performed entirely at the buyer's terminal.

- suffix number is associated with only a small percentage of items because of additional variations from a standard designation. If the suffix number is known it should be entered. However, if the suffix number is not known an asterisk may be entered and all variations for that basic item will be listed.

- the next step requires the operator to enter the quantity of the particular item desired, as indicated at 78. If prices for several different quantities are desired, the largest quantity should be entered.

- the inquiry is sent, in batch, to the central computer 38.

- the computer immediately searches its memory (the process is depicted in steps 80-98) and returns a response, as indicated at 100, in batch, and then disconnects.

- a typical response to an inquiry like that in Table III, is shown in Table IV.

- the field titled "INQ QTY” just repeats the quantity of a particular item listed in the original inquiry entry.

- the field titled “SPLR” shows a four letter code which identifies the supplier.

- the field titled “COST” is the net price the buyer will pay for the item regardless of the quantity ordered. If there is a quantity discount schedule, this field will say "BELOW” and the various quantity/price reductions will be shown on the next two lines.

- the field titled “U/I” shows the units for the price. If the unit is “M”, “C”, or “Ea.”, then the quantity is in numbers of pieces. If the unit is "Lbs”, “Ft”, etc. then the quantity is based on that unit.

- the field titled "BX QTY" shows the number of pieces in a full container. If the order quantity is not an even increment of the box quantity, then a surcharge may be added to the buyer's total cost. If the item is prepackaged in a fixed quantity package, then this field will blink indicating that only even increments of this quantity may be ordered. If a supplier or vendor offers both prepackaged and bulk quantities of an item, then each item will be displayed on a separate line.

- the field titled "PRODCTN" indicates the number of pieces that are in production by the supplier. The operator may display the earliest scheduled delivery date for a

- the operator may have five options. They are: 1) exit the application; 2) print a copy of the inquiry reply (quotation) for the customer; 3) print a copy of the inquiry reply for the buyer's own files; 4) store the inquiry reply in the local history file; or 5) place an order for some or all of the parts. If a quotation is to be printed for the customer, the operator will enter the selling prices and delivery promises and then print out the quotation on his company's letterhead or quotation form. An inquiry reply copy for the buyer's own files can just be printed as is or with the quote to the customer added on (see Table V below). If the inquiry reply is to be stored, then it will be stored in the local history file where it will be ready for recall if a matching item and customer inquiry is entered later. This inquiry reply can also be recalled and modified to serve as an order entry.

- the top part of the Purchase Order Screen is called the Header Screen. This Header Screen need only be filled in completely when the shipment of the order is other than directly to the buyer by normal freight.

- a '0' is entered to permit an item (indicated at 102), quantity

- the operator selects option '1' to signify this completion and the entire purchase order is sent, in batch, to the central computer 38.

- the central computer 38 Upon receipt of the order, the central computer 38 first checks to insure that the buyer has any remaining credit, indicated at 108. (As a subscriber to the system, the buyer must establish a stand by letter of credit with a particular bank in order to purchase any items.) If the buyer has credit, the quantities requested are examined against current warehouse inventory (indicated at 134). If the quantities requested do not exceed the inventory then the total monetary value of the order is calculated and compared to the value of the buyer's currently available line of credit (indicated at 122). If the amount of the order does not exceed the buyer's credit, and all previous criteria have been met the order is accepted (indicated at 126).

- a sample Order Acceptance Screen is shown in Table VII, below.

- the acceptance screen supplies a system order number, the shipping weight, the cost of the goods including all extra charges and the estimated shipping charges.

- the central computer will send an order rejection (indicated at 120 and 136, respectively) which is displayed as an Order Rejection

- the order is rejected for credit reasons it can be modified to an acceptable total monetary value. If the order is rejected for insufficient stock it can be modified to limit the quantity ordered to the amount in stock or less.

- the buyer may inquire, through the system, to get the scheduled delivery date for all items that are currently in production by the supplier. These dates are subject to revision as the supplier schedules his production lines and thus cannot be guaranteed.

- the buyer When the reserved parts are received in stock, the buyer will be immediately advised of that fact by the central computer during (indicated at 166) an off-hours transmission to the buyer's I/O device and the reservation will be automatically removed from the reservation file (indicated at 167). The buyer then has the option to enter an order for the parts, as described above, if he still needs or wants them.

- the buyer may add, change or delete reservation items at amy time. As such, he may display all his

- a Reservation Screen is generated which requires the operator to enter the item number (indicated at 140), any suffix, the supplier code (indicated at 144) the quantity (indicated at 142) and optional internal remarks (which permit a buyer to track his reasons for ordering) and external remarks (which are reported to the supplier).

- the screen is filled in, it is sent, in batch, to the central computer 38.

- the central computer 38 returns a Reservation Estimated Delivery Screen which lists the most current information on the quantity in production and the expected arrival date of the product(s). (see Table X).

- the system returns a summary of all orders.

- the summary includes: the system order number; the buyer's order number, if any; the method of shipment; the date shipped; the shipping charges and the order value, (see Table XI).

- the billing procedure is illustrated in the flow chart of Figure 6.

- the letter of credit can be for any amount designated by the buyer. For ordering purposes, the total of all unpaid invoices and new orders cannot exceed the credit amount.

- the suppliers will simultaneously be credited for the value of their parts that were shipped, by the same electronic funds transfer program (indicated at 170). They too will receive a report detailing the items shipped and their destination. This report is also downloaded from the central computer 38, during off-hours in batch.

- containers for each item are brought together, and a receiving entry is made into a nearby terminal 186 which is linked to the central computer 38.

- Individual labels are printed for each container that indicate which random storage location the container is to be stored in. (See Table XII, below).

- a bar code label is also affixed to each container to identify the individual container.

- the computer record for each container will carry the shelf or pallet location, the part number, the quantity in the container, the supplier identification code, the date received, the supplier production order number, the source batch control number, the gross weight of the container and the bar code record. (See Table XIII for the screen used to enter new receipts).

- the first system provides for two storage sections, "A" and “B” as shown in Figure 7.

- Section “B” 188 is for all full and sealed containers, while section “A” 190 and 192 is for all open containers. Only one open container of each item is maintained.

- containers When containers are received in the warehouse, they are initially assigned a "B" storage location. Only one open container of a particular item can be stored in a single “A” storage location.

- the "A” containers can be further divided into two categories, such as cartons 192 and kegs 190 (e.g. cartons will weigh up to 50 pounds and kegs will weigh over 50 pounds). The sole purpose for this division is that when fill orders for partial container quantities are filled, the carton is brought to a counting scale, while a counting scale is brought to the heavier kegs.

- the second storage procedure employs four separate storage areas designated "A”, "B", “C” and “D” as shown in Figure 8.

- Storage area “A” is virtually the same as area “A” in the previous system.

- the "B” area 188* is for full containers. Only one container will reside in each location. Further, the "B" area 188' is subdivided into sections by container size.

- the "C” area 210 is also for full containers. However, in the "C” area 210, each location is capable of storing multiple containers of the same item and batch. It too is subdivided into smaller sections according to container size. By storing multiple container in the same shelf location, space is saved by eliminating intervening shelves.

- the "D" area 212 is for full pallets of incoming containers. If the entire pallet consists of cartons or kegs of the same item, the most efficient way to store them is on the pallet without removing the containers.

- This second system is designed to maximize the density of storage while minimizing the labor to handle the containers and pallets. In order to do this, certain guidelines are followed by the system:

- containers may be removed from the "D" section either to be shipped directly to the customer or to replace a container in "A" that has been depleted,

- Orders will be picked in a batch environment.

- the central computer 38 calculates the weight and volume required for that order and assigns a cubby hole in the consolidation shelves area 198 large enough to accommodate all the items. If more than one order in the batch is being shipped to the same designation, each order is flagged so that they can be combined in a single shipping container.

- Three sets of labels and two sets of documents are printed for each batch of orders. These documents and labels control the movement of containers from the "B" area to the customer to the "A" area to the customer, and from the "B" area to the "A” area.

- One set of documents is the actual picking lists that will eventually be included with the shipment.

- the other set of documents lists the "A" to customer shipments. This set of documents is actually identical to the set of "A" to customer labels, but contains additional information which is used in conjunction with an "A" control card.

- These labels and documents include bar codes that are checked against the labels pasted on the containers so that the shipment of the correct parts is verified.

- one set of labels controls the movement of full “B” containers being sent to the "A” area to replenish an "A” box that will be exhausted. (See Table XIV). These "B” containers are pulled first to enable the "A” to customer counts to

- a second set of labels controls the movement of full containers being shipped directly to the customer. (Table XV). These containers are pulled after the "B" to "A” containers have been pulled.

- the third set of labels is used to pick the "A" to customer items (see Table XVI, below). If the items to be picked from the "A" area are stored in cartons, the labels are given to a person who takes the cartons off the "A" shelf and brings them to conveyors 200. The labels are placed in the open containers which are put on the conveyors 200 bringing them to scale count tables 194. The quantity necessary to fill each order is taken from the cartons, and put in small bags or boxes. The "A” to customer labels are pasted on these containers. The original "A" cartons, or “B” to "A” carton, if any were needed, are placed on a return conveyor 200 which carries the cartons back towards the "A” area. The same process is followed for "A” kegs, but since kegs are much heavier, the scale is brought to the kegs at 190.

- the person counting the parts has a computer printed report listing the same data that is printed on the labels.

- the report also includes additional data that is used with information printed on a card which is pasted to the front of each "A" container.

- This "A" Control Card is used to keep a running balance of the quantity of parts remaining in the container.

- the card also assigns a

- control card transaction data from the printed report to the control card is an additional guarantee that the correct parts are being shipped to the customer. (This control card is explained in detail below).

- the second printed document list which is a packing list is ultimately sent to the customer with his order. This document is sent to the assembly table 196 prior to the arrival of picked cartons. If the order calls for two or more items, this packing list is placed into the appropriate cubby hole to await all the items. If the order calls for only one item, the packing list is held at the assembly table 196 without placement into a particular cubby hole. In such a situation, the item is sent to the shipping area S, via conveyor 202, as soon as it reaches the assembly table 196. In an order requiring a plurality of items, the containers of those items are placed in the appropriate cubby holes based on the cubby hole number printed on each label. When the last item has been brought to the cubby hole, the order is sent by conveyor 202 to the shipping area S.

- the shipping area S has two locations.

- the first location is for heavy orders which require shipment by commercial freight 206.

- the second location is for lighter orders which can be sent by UPS or the like 208.

- a source batch control number is printed on the label which is placed on the face of each carton. These numbers are also recorded in the computer record for each container. When any container quantity is to be shipped, these reference numbers are again printed on the label that will be pasted on the front of the container in which the item will be shipped. These numbers are also printed on the packing slip and invoice and are retained in the computer memory for a number of years after shipment.

- the inspection documents can be electronically scanned when the parts are first received. This data can then be held in the computer memory. Whenever an order calling for these special containers is processed, the inspection documentation automatically prints along with the packing slip and invoice.

- the original receiving label When the original receiving label is pasted on the front of an incoming container, it includes a "self-check” digit. This is a parity check that validates the shelf location number. When the label used to ship the container or move it to the "A" area is printed, it will show the same self check digit. This new label will be pasted next to the original incoming label, and the two self check digits will be compared and circled by the stock person. If the two check digits do not match, the wrong container was pulled.

- Parts which come from an "A" container also have a fail-safe control.

- This control comes from the "A" control card which is pasted to the front of each "A" container. (See Table XVII, below).

- the card functions similarly to a checkbook record. The quantity removed is subtracted from the prior balance and any additional quantities (via "B" to "A” container transactions) are added.

- the card also shows the transaction quantity, the new balance, the date, the transaction number and the warehouse person making the transaction. This same data is printed on the report used by the person at the scale count tables 194. When that person receives the container, he must transfer this data from the report to the control card, and enter his initials and the date. If the opening balance does not match, or if the transaction number is different, the wrong container has been pulled. If an error occurs, the transaction can be reconstructed and the record set straight between the two items; the one that should have been shipped and the one that was actually shipped.

- a sample "A" control card is shown in Table XVII.

- Each card is designed to hold twenty entries in two columns of ten each.

- the digits 0 through 9 at the sides of the card are preprinted.

- the label at the top of the card is automatically printed by the central computer 38 after every twenty entries, and is included in the sequence of "A" to customer labels.

- the two digits, in this case 46 and 47, printed on the label in the lower left and lower right corners, are the first two digits of a three digit sequence number referred to in the "A" to customer listing.

- the top entry in the left column is really sequence number 460 while the second entry from the top in the right column is sequence number 471.

- orders are maintained in the central computer 38 in accordance with the description provided earlier.

- the central computer 38 can be called upon to create and print out an order picking list.

- An example of such a picking list is shown in Table XVIII.

- Each item to be counted to fill an order is separated by a dotted line on the picking list.

- the data on the first line of each entry shows the "A" box location, a "self check” digit, the part number, and the item

- the transaction data will be copied to an "A" control card by a warehouse operator. Before removing the parts from the box, or making the "A" control card entry, the operator must verify the "self check” digit by circling it on this listing. Thus, when the data itself is entered, the operator will be verifying the opening balance and the sequence number. The first three columns of data are transferred to this "A" control card as well as the date and the operator's initials. The sequence number is pre-printed on the control card and does not have to be entered.

- Table XIX depicts a typical customer packing list. This shipment is going to a buyer. If it were being shipped directly to the buyer's customer, the "bill to” would show the customer's billing address and the "ship to” would show the customer's shipping address. The order number would be the order number that the customer gave to the buyer. The names “Zenith” and “Top Notch” are the supplier names. If the shipment went directly to the customer, these would both read “Titan", the buyer's name.

- Weights are used as a secondary means to ensure that the correct parts are being shipped. As parts are received in the warehouse, the gross weight of each

- the system calculates the weight of the entire order.

- the weight of the quantity shipped is estimated as a percentage of the net weight of the original container. This estimate is further matched against the actual net weight for each partial container quantity when the parts are on the counting scale.

- the counting scale reports the net weight to the warehouse local computer in conjunction with the bar code checks that will also be made (see below).

- the estimated gross shipping weight of the order will be printed on the packing list as a guide for the shipping clerk.

- the weight, quantity, container size, date received, and batch control number of the last container received are stored in the item number master record.

- the ratio of the new container quantity and weight is compared to the old container quantity and weight. If there is a wide discrepancy the receiving clerk is notified and the matter can be investigated further,

- PC's there are two local warehouse computers or PC's in an individual warehouse 186 and 212. These PC's serve to off-load some of the work from the central computer 38, such as validation and data collection.

- the first PC 186 is for receiving and the second is for picking and/or shipping 212.

- the data required consists of open replenishment orders, the last receiving weight data on the inventory master record, the self container size file and the next available "B", "C” or "D" area shelf locations.

- the order data is down-loaded to a PC after each batch of packing lists and labels is printed.

- the data includes information on all "A”, “B”, “C” and “D” containers, and the weight for each item.

- the full container weight will come directly from the receiving weight stored on the "B", “C” and “D” container records.

- the partial container weight will be calculated from the full box weight in the container master file.

- a bar code label is affixed to the face of the container.

- This bar code label may be either pre-printed or printed by the PC 186 at the point of entry into the warehouse 184.

- the bar code label is affixed to each printed location label which is also affixed to the container.

- the bar code is scanned and thereby linked with the record which supports the receiving label (Shown in Table XII).

- Associated with the downloaded record of each order is the record of the bar code for each container.

- the "A" container bearing its original bar code label is brought to the counting tables 194.

- a person at the counting tables 194 enters the order number and scans the bar code label on the "A" container. If the proper "A" container has been brought the PC 212 will verify this. If an improper container has been brought, the PC 212 will indicate that the container does not belong with that order.

- a new bar code label is affixed to that container and scanned. The PC 212 then substitutes the new bar code number for the old bar code number in association with the "A" to customer label for this particular order.

- the original bar code label remains on the "A" container and further remains associated with that container's current label .

- a master menu is available to each supplier which lists the options he may access in interacting with the warehouse system.

- the first option Maintenance Inventory Records, permits the supplier to add or delete items to be maintained in the warehouse system and to change selling prices of the particular items maintained in the warehouse system.

- the Maintenance Working Tables option allows a supplier to designate his lead time to manufacture his product, to prohibit certain buyers from purchasing his products and to designate certain discounts or adders for individual customers.

- the option titled Replenishment Orders permits the supplier to indicate when a new supply of a particular item will be sent to the warehouse system and in what quantities.

- the Inquiry option is virtually identical to the inquiry option available to a buyer. In this case, it simply allows a supplier or vendor to determine current price and availability of parts for his own customer from his own stock in the warehouse system.

- Subscriber Distributer or Others permits a supplier to place an order for any of his parts maintained in the warehouse system to be shipped to either a distributer who subscribes to the warehouse system or anyone else who deals directly with the supplier or vendor.

- the warehouse system does not build a barrier between the supplier and his customer. Instead it acts as a filter relieving both supplier and customer of laborious inquiries and orders for small quantities.

- the customer is encouraged to call the supplier for additional discounts on large quantity orders, (see Figure 5, step 158) If such a discount is granted the order must be put in by the supplier so the system will know that the price is authorized.

- the entry of orders for non- subscribers occurs frequently when the supplier maintains his entire inventory in the warehouse system. In such cases, all direct orders from the supplier to his customers are necessarily handled in this manner,

- Table XXI When the Maintenance Inventory Records option is selected from the Master Menu Options Screen, the screen shown in Table XXI is displayed. This screen is used to add a new item, change or delete data for an existing item, change descriptions for non-generic or generic items, and change descriptions for items with suffixes . It can also be used to add, delete and display alternate and substitute item numbers.

- the supplier When an item is added to the system, the supplier designates a base price, a product category and the lead time for that item.

- the lead time specified determines when the warehouse system notifies the supplier that it may be time to replenish the inventory for that item.

- the lead time should include the time to produce the parts , as well as the paperwork processing time, shipping time and a reasonable safety factor. As indicated previously, the decision to produce new parts and the quantity to be

- the warehouse system can store the sales quantities for a period of time, and based on this period of time can determine the monthly usage by employing an algorithm.

- the supplier may add or delete items at will. If an item is deleted, it will be flagged as such and will remain in the system until the end of a year or until there is no more inventory available, whichever is later. No notice about replenishment of stock will then be sent to the supplier. As in the buyer systems, this screen is generated locally and the information is input off-line. Once the information has been input, it is sent, in batch, to the central computer 38.

- Table XXII is a Product Code Table.

- the Product Code Table allows the supplier to designate a discount or adder to be charged to all items belonging to that product code group.

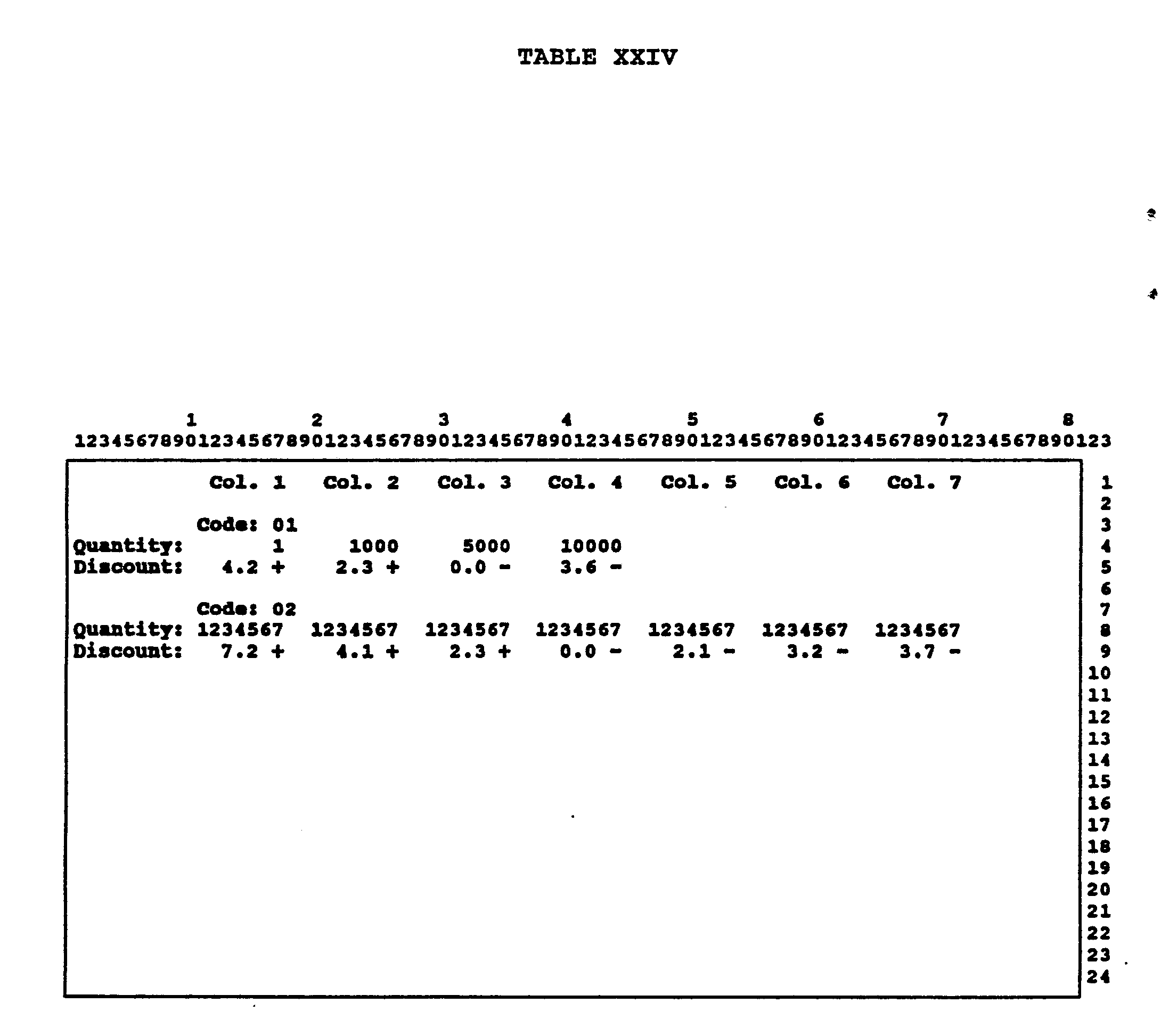

- the Distributer Discounts File shown below in Table XXIII establishes specific discounts by code. By later associating that code with a particular distributor, the appropriate discount can be calculated.

- the supplier can enter any number of discounts as a percentage variation from the base price.

- This percentage variation is based strictly on the inquiry quantity or quantity ordered.

- a Lead Time Table for a particular group of a supplier's products can be designated.

- Table XXV which shows the Lead Time Table Screen demonstrates that capability.

- the supplier also has the ability to specify price by particular unit of issue. He does so by selecting standard codes which indicate what units are being used to calculate prices. (See Table XXVI, below).

- the supplier can also display whether a product group is, in fact, a generic or non-generic product as designated by the system. This information can be obtained through the screen shown in Table XXVII, below.

- the product group is identified by a prefix associated with the part number which the computer uses to make the generic/non- generic designation.

- Table XXVIII Another screen available under the Maintenance Working Tables option (Table XXVIII, below) allows the supplier to display the size and weight of the cartons he uses. This information permits the accurate calculation of the weight of individual pieces of an item in a full carton. These figures are also used to determine the cubic size of the containers which may be used to calculate storage charges.

- a supplier wishes to indicate when additional stock is expected to arrive to the warehouse system, he can do so by choosing the Replenishment Orders option. He can input the quantity in production as well as the expected arrival date (see Table XXX, below).

- the supplier can update his replenishment information through the screen depicted below in Table XXXI,

- the supplier provides the quantity shipped, the method of shipment or carrier, the expected arrival date, the date shipped, and the number of containers shipped.

- the invention provides for a comprehensive warehouse and ordering system.

- the ability to ship items from a multitude of suppliers in a single shipment such that each item is purchased at an optimum price or from a particular desired supplier is likewise, a major improvement.

Abstract

An integrated parts ordering system and method and warehousing system and method is provided. The parts ordering system and method employs computers (34, 36, 38) to allow a buyer to obtain information about particular parts maintained in the warehouse system (32). The parts are owned by a plurality of suppliers. The price of the parts, quantity in stock, and other information is provided to the buyer by the system. An electronic purchase order may be prepared and transmitted to the central computer (38). The central computer (38) may also be used to maintain and control inventory in the warehouse system (32). The central computer (38) can generate picking lists and verify buyer's orders for shipment. A method and system is also provided for electronically transferring funds to cover payments for items purchased by electronic purchase order and filled by the warehouse system (32).

Description

INTEGRATED ELECTRONIC PARTS WAREHOUSING

AND DISTRIBUTION SYSTEM AND METHOD A. FIELD OF THE INVENTION

This invention relates to warehousing and distribution systems and methods, and particularly to such systems and methods for warehousing and distributing

relatively small items such as fasteners, electronic parts, office maintenance supplies and the like.

B. BACKGROUND OF THE INVENTION

1. Prior Ordering Systems

The purchase, supply, inventory maintenance, and payment processing of relatively small items such as

fasteners, electronic components and office maintenance supplies, items which are required to be supplied

repetitively and in significant quantities, can be

relatively time consuming, expensive and result in rather complex, unreliable manual procedures.

In a typical ordering process, a buyer wishes to purchase a specific item. If the buyer has a source book which lists multiple suppliers of a variety of items, he can look up the names of more than one supplier. Further, if the buyer has obtained catalogs from any of those suppliers, he can look up the item to obtain price and delivery

information. However, in the typical situation, the buyer must call or write to the particular supplier in order to make certain of prices because the catalog prices are frequently out of date. Further, if the buyer wishes to have catalogs, usually he or she must call or write for the information.

The source book itself also causes additional problems. First, it usually is revised only infrequently and thus often is out of date. Additionally, the source book lists suppliers who may no longer handle the item, or may handle it only as a convenience to their customers and do not maintain it in stock. This means that they probably cannot provide fast delivery and that their prices will most likely be considerably higher than others. Further, the

suppliers may no longer be at the listed location or even in business. Attempting to call or write to any of the above suppliers, clearly wastes a large amount of a buyer's time.

Even when the buyer purchases the item on a somewhat regular basis, he may not be aware of the current prices charged by the regular suppliers, or be aware of any new suppliers who have entered the market. Thus, the buyer often will miss the best price or supplier unless he spends a considerable amount of time in investigation.

After choosing a particular supplier, a buyer wishing to place an order usually must prepare a written purchase order and mail it to the supplier. The supplier typically acknowledges the order in writing, giving expected shipping dates, and other pertinent information. Of course, the supplier also can refuse the order. All of this written communication can go on for days or even weeks.

Orders can also be given by telephone. This can be a much faster system if the proper person can be reached at the supplier's place of business. However, this approach is less than fully satisfactory because it increases the chances for error in that spoken words are frequently not reduced to writing for visual verification. Even if the order is reduced to writing, it easily can be written incorrectly, thus creating an incorrect order.

Even the use of a written purchase order can create opportunities for error. If purchase orders are prepared or typed by someone other than the buyer, there can be an error in communication or typing. Further, when an acceptance is prepared by the supplier, additional errors can occur. Beyond that, communications may be lost, delayed or even destroyed by mail handling.

Still other errors may be caused by differences in nomenclature and specifications for particular items. Many suppliers have their own names and part numbers for specific items. Both the deviation in name and part number can cause numerous errors since each usually must be looked up and verified for each different supplier. This not only creates an additional source of errors, but takes still further time.

When ordering modest quantities of a relatively large number of different items, it is often most cost- efficient to consolidate those orders with one or a small number of suppliers. Typically, the selection of the suppliers is made haphazardly and the lowest total price is often not obtained.

A still further problem in the buying process is caused by the difficulty or inability of supervisory

personnel to determine whether the buyers are purchasing on a best-price basis, or have otherwise been dealing with suppliers in an appropriate manner.

Computerized electronic supply systems of a wide variety have been proposed in the past in order to alleviate some of the foregoing problems.

In one type of prior system, a single buyer had contracts with various suppliers whereby the suppliers agreed to sell specific items at specific prices. The buyer punched cards, one for each item, which were read and the information transmitted over telephone lines to the

specified vendor. The vendor's equipment punched card corresponding to those received by the buyer, to be used as an order to be filled by the vendor. Such a system did not provide any means for identifying multiple vendors for a given item, or for operating other than on a contract basis. Thus, the buyer could not quickly shop for the best price or terms from a variety of vendors.

Other systems have been provided whereby orders for a variety of vendors from a particular buyer are

collected, sorted and accumulated according to vendor.

Then, a batch of orders is transferred electronically to each vendor. Such a "clearing house" operation also does not provide a solution to the vendor's selection problem, and has other shortcomings.

Some direct electronic connections have been made between a specific vendor and a specific buyer by use of a video screen. The buyer can call up on the screen a

purchase order form, fill it in, and transmit it directly to a similar terminal at the vendor's place of business.

However, such an arrangement also does not solve the

vendor' s selection problem and falls short in other

respects.

Yet another system collects information from suppliers concerning their surplus inventory. A

computerized database or directory of this surplus inventory is thus created. In practice, a buyer accesses this

database from a terminal at his location to ascertain suppliers who are offering the particular item he desires. Occasionally, the prices at which the item is offered for sale are also displayed. The buyer, after obtaining this information, usually must then contact the particular supplier or suppliers directly. Since this system often is not updated regularly and often involves odd lots of less commonly used items, it is not always helpful. Further, items listed frequently are not in stock since, once the surplus is gone, there may be no additional inventory available for sale. Lastly, when prices are shown, they are not necessarily current.

Another system which was proposed had suppliers or vendors listing their items on a central computer, along with their current price schedule. Buyers who subscribed to the system were to be able to access the central computer which would display on a computer screen the particular item and the various suppliers offering that item along with the current prices. When a supplier wished to place an order he could prepare an electronic purchase order which would be sent via the central computer to the vendor's terminal. The vendor could then respond any time after receiving the order with either a confirmation, change of price, or rejection. Further, this system still required the vendor to accept or reject the order and to ship the products from his location. Such a system still failed to optimize the ordering and shipping procedures.

2. Prior Warehousing Systems

Historically, inventory control in warehouses has been maintained manually, for example, on file cards. Each card controls a single stock item, or stockkeeping unit ("SKU"). The file card shows the current quantity of each item on hand. The quantity listed usually has not been

verified by physically checking the items in the warehouse. A running balance is maintained by deducting shipments and adding receipts. Most conventional computerized warehouse systems still keep records in substantially the same way; that is, by creating and maintaining files by stockkeeping unit.

In practice the SKU quantity shown on a card or in a computer file has no actual existence as a single,

discrete unit in a warehouse, but rather is the sum of items physically contained in several warehouse units or

containers, the number and locations of which can change daily. In the absence of fail-safe computerized control over such items, a large warehouse can experience any number of inventory difficulties. This is especially true where a relatively large inventory of small parts is maintained.

Some of the problems with such prior systems are the following: incorrect shipments; misplaced part;

pilferage and inaccuracy of the records as to the amount of stock actually on hand. Other problems include delays in shipping; insufficient use of warehouse space; excessive labor costs and methods.

In Canadian Patent Number 1,188,814 issued June 11, 1985, of which the applicant is a co-inventor, the above problems are addressed, at least in part. The disclosure of that patent hereby is incorporated herein by reference.

While the last-described system offered numerous advantages over prior systems, it left substantial room for improvement in the areas of accuracy and speed of filling orders, labor costs, and efficiency of utilization of warehouse space.

3. Distribution by Manufacturers and Importers

Most manufacturers or importers of fasteners and similar items carry an inventory of fast-moving items to supplement their production schedules. This provides an extra service for their customers, and allows them to smooth over their production or purchase orders by producing parts for stock when sales are slow. Once this stock has been produced, however, its control usually is not very efficient because of some or all of the foregoing problems.

Usually, a complete warehouse operation must be maintained, even though the range of items carried is fairly limited because it reflects only the items manufactured by the owner of the warehouse. This can be very costly.

The manufacturer's telephone salesperson usually are trained by quote prices for large production orders, for which they may receive a significant commission. They may consider the process of quoting price and availability for small stock quantities to be a waste of time, especially if they receive many inquiries but few orders. The warehouse may not be geared to ship small quantities of an item, nor to make some day shipments when requested. Therefore, the smaller orders are lost, and with them the larger follow-on orders which can be so valuable.

The manufacturer may run out of stock on active items, thereby generating more non-productive inquiries.

Therefore, with only a narrow product range, and the

possibility of active items being out of stock, the

potential buyer probably will call other sources first.

When the manufacturer receives only a small share of

inquiries for the items in this inventory, the value of his investment in the warehouse is seriously reduced.

There are special problems with proprietary items. After the manufacturer of proprietary items expends a great deal of time and money in convincing engineers to design their product into the final assemblies, a network of authorized distributors is usually put in place to make the purchasing function more efficient. These authorized distributors are expected to give some technical advice to the user and to stock a representative range of time to offer quick delivery.

A problem often occurs with the non-active items. With these times, the distributor is wary of carrying too large an inventory without a reasonable return on his investment, yet it may not be available when needed from the manufacturer's stock. The authorized distributor is then almost forced to carry these items in his own stock in order to be able to service the occasional orders he may receive.

If the resulting erosion of profit is too severe, the

distributor may refuse to carry the product at all.

The overseas manufacturer also has special problems. Currently, an overseas manufacturer has roughly three options for selling his products in the U.S.

One option is to carry no inventory in the U.S., and to sell only by shipping directly to the customer. Such sales usually are for large quantities with a long lead time, and are usually very competitively priced. Sales are usually made through U.S. or overseas based trading

companies, independent sales agents, or by the

manufacturer's own direct sales staff. In many cases, the customer does not know the name of the manufacturer, and for repeat orders, the customer may move to another manufacturer if he receives a lower price or quicker delivery. Thus, the manufacturer loses follow-up business, and often must suffer with extremely modest profit margins.

A second option for the foreign manufacturer is to place a consignment inventory at one or more stocking distributors in the U.S. This has the advantage of opening the market to more customers, but the manufacturer is limited to the sales and marketing scope of these

distributors. They simply may not be reaching anywhere near the full potential market for the product. If there is only one distributor, there is only limited coverage, while with more than one distributor, the inventory investment is multiplied, while the incentive for the distributors to sell the product is reduced. The cost for this service may be high, and this may make the price of the product non- competitive.

A third option is for the foreign manufacturer to open his own warehouse in the U.S. This is probably the most costly option of all. The manufacturer must pay for the purchase or rental of a warehouse, buy or rent a full range of warehouse equipment, staff the warehouse and office operations, and still have to pay for a full sales and marketing efforts, he probably can reach only a small portion of the potential customers.

C. SUMMARY OF THE INVENTION

Accordingly, it is an object of the invention to provide a system and method for alleviating the foregoing problems and improving upon the prior systems and methods.

In accordance with the present invention, there is provided a system and method for electronically

communicating information regarding the identity of

suppliers for selected physical items. The system and method allow the buyer to quickly obtain the name of at least one vendor, and preferably a substantial list of vendors, for any one of a large quantity of different items. Moreover, the buyer is provided, at the same time, with the prices charged by each vendor for the item and the

quantities desired by the buyer.

Preferably, the physical items are stored in a central public warehouse containing products owned by many different business entities. The information communicated to the buyer is for the items in that warehouse.

It is also preferred that the system and method provide electronic communication between the buyer and a central computer which maintains a running inventory of the public warehouse system as well as additional pertinent information including suppliers' names, business history, prices and re-supply schedule.

In practice, the buyer can inquire as to the availability and pricing of a multitude of items maintained by the central public warehouse system by inputting part numbers into a local input/output ("I/O") device and

electronically communicating those parts numbers to the central computer, in a batch. The central computer then provides a list of vendors who maintain an inventory of the particular item within the public warehouse system, the price of the part charged by each vendor and the quantity of that item in stock and available from the public warehouse system. The buyer can create a purchase order on his I/O device, which is then electronically transmitted to the central computer. This, order is then conveyed to the public warehouse system by the central computer for processing.

In a preferred embodiment of the system and method, the central public warehouse system electronically communicates with the central computer to maintain a running inventory of the items stored in the warehouse system. This communication also is used to provide a comprehensive warehouse control system which not only directs and

maintains individual item's locations within a given

warehouse, but also prepares picking lists, warehouse movement directions and shipping documents in response to orders received electronically from a buyer's input/output device.

Data is maintained by the central computer on the frequency of inquiry of buyers for each particular part stocked by a vendor, orders placed, etc. Suppliers can electronically obtain this data by communicating with the central computer through an I/O device.

It is also preferred that the buyer maintain a letter of credit with a pre-designated bank such that sometime after the transmittal of an electronic purchase order to the central computer the necessary funds may be wire-transferred through the pre-designated bank to the vendor. This eliminates the processing of checks and the like through each party's respective accounting department. Both the buyer and the vendor save time, effort and money by using the electronic transfer system. The elimination of billing invoices and checks greatly reduces the labor necessary to complete a purchase.

In a warehouse associated with the present

warehouse system, it is preferred that all items be stored in four functionally distinct storage areas. Three of these storage areas are for full containers while the fourth is for open containers. The first of the four storage areas is for full pallet quantities of a single item or a single container size. The second storage area is for multiple containers of the same item and the third storage area is for single containers of an item. The use of these four storage areas provides a substantial benefit over prior systems by maximizing storage density and minimizing container handling.

A central computer, which is the same computer as that which is used to accept inquiries and orders from buyers, is used to assign random storage locations in each of the three full container storage areas. This assignment is done as shipments are received in the warehouse. At the time shipments are received, computer generated labels as well as bar codes are placed on each incoming container.

The labels provide a variety of information about each container including its intended storage location, supplier, part number, etc. The bar code is used strictly to identify each container. This bar code information is stored in a local warehouse computer (PC) along with the label

information. At the end of each business day all receiving records are up-loaded to the central computer from the local warehouse computer. Certain other information is downloaded to the local computer from the central computer as needed.

The computer system directs the movement of the containers in the warehouse. In response to orders which have been input to the central computer by buyers (and sometimes by vendors) the central computer generates

"picking" lists. From these lists, items are picked for shipment. This picking involves the pulling of full

containers of the items as well as the assembly of partial container quantities. As such, containers are moved around in the warehouse from each of the four storage areas. In each case, the movement is accompanied by a newly generated computer label which includes the new storage location or customer information as well as the other information which was recorded at the time of the container's receipt. With each movement, the container's bar code is also scanned to verify that the proper container is being moved. After particular orders have been picked and organized they are sent to a shipping area. At the shipping area, various documentation which has been generated by the computer in accordance with the order and the information stored upon receipt, is reviewed. This is the final check of the order before it leaves the warehouse and is accompanied by a

complete scan of each individual container's barcode. Thus, the integrity of the order is verified.

The use of the bar codes virtually guarantees that orders are being shipped correctly and that the inventory is immediately retrievable from a given location. The use of the four storage areas substantially improves the

warehouse's storage density while minimizing container movements. Further, by employing local microcomputers (PCs) there is a substantial savings in central computer usage and communication costs (if the central computer is located off- site).

When this automated warehouse system is coupled with the previously described electronic ordering system, efficiencies of scale are realized.

The public warehouse system permits specialization in a given market. Thus, when all the suppliers to the warehouse system are concentrated in a single industry, with a clearly defined customer base, it is possible to provide more options than would be available otherwise.

Particularly, buyers can access the warehouse system's composite inventory database to obtain instant quotations and place orders for immediate shipments based on current inventory. This can be done despite the fact that items may be from several different suppliers. In most previous systems, the buyer's computer access was limited to a single supplier.

With the present system, there is no paper work necessary to transfer an order to the warehouse for filling. The buyer, who was able to select his desired items from a variety of vendors and prices has undoubtedly had his information gathering effort minimized. This is because he does not need to make phone calls to get competitive prices and available information. Further, the buyer's shipping costs may be greatly reduced if he has ordered items

provided by multiple suppliers. Previously, such orders would have required shipment from each supplier's location, thereby multiplying the shipping costs.

Paper work is also minimized since no actual purchase orders are sent. Lead time is cut down since the

order need not be called back in by the buyer to a chosen supplier and can be shipped almost immediately. The order is transmitted electronically to the central computer used by the warehouse system and can thus be filled right away. The order is further expedited since the items are

necessarily in stock and available for shipment.

The buyer also has the ability to enter reservations instead of placing conventional backorders with a single supplier. With the reservation system each

supplier that can furnish the part is advised of the buyer's need, and the system will report to the buyer when parts become available from the first supplier. In effect, the customer has placed a backorder with all the suppliers capable of furnishing the item. This can greatly decrease the time to completely fill an order. The customer can receive weekly reports showing all the suppliers' shipping promises. Thus, any time consuming telephone follow-ups may be eliminated.

The warehouse, operating efficiently because of the two or four storage area system is capable of shipping many orders with minimal labor costs. The number of

warehouse locations is minimized by the high density storage capacity.