WO2013173657A1 - Low burst sustained release lipophilic and biologic agent compositions - Google Patents

Low burst sustained release lipophilic and biologic agent compositions Download PDFInfo

- Publication number

- WO2013173657A1 WO2013173657A1 PCT/US2013/041466 US2013041466W WO2013173657A1 WO 2013173657 A1 WO2013173657 A1 WO 2013173657A1 US 2013041466 W US2013041466 W US 2013041466W WO 2013173657 A1 WO2013173657 A1 WO 2013173657A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- composition

- rapamycin

- polymer

- drug delivery

- embodiment provides

- Prior art date

Links

- RYTNUBMUCRZNKN-UHFFFAOYSA-N CC(CCC(ON(C(CC1)=O)C1=O)=O)=O Chemical compound CC(CCC(ON(C(CC1)=O)C1=O)=O)=O RYTNUBMUCRZNKN-UHFFFAOYSA-N 0.000 description 1

- AMIRCKWZMUULOA-UHFFFAOYSA-N CC(CCCCCCC(ON(C(CC1)=O)C1=O)=O)=O Chemical compound CC(CCCCCCC(ON(C(CC1)=O)C1=O)=O)=O AMIRCKWZMUULOA-UHFFFAOYSA-N 0.000 description 1

- OOIYIJYGRWRSTC-UHFFFAOYSA-N CC(CCCCCCCCC(ON(C(CC1)=O)C1=O)=O)=O Chemical compound CC(CCCCCCCCC(ON(C(CC1)=O)C1=O)=O)=O OOIYIJYGRWRSTC-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/06—Organic compounds, e.g. natural or synthetic hydrocarbons, polyolefins, mineral oil, petrolatum or ozokerite

- A61K47/08—Organic compounds, e.g. natural or synthetic hydrocarbons, polyolefins, mineral oil, petrolatum or ozokerite containing oxygen, e.g. ethers, acetals, ketones, quinones, aldehydes, peroxides

- A61K47/10—Alcohols; Phenols; Salts thereof, e.g. glycerol; Polyethylene glycols [PEG]; Poloxamers; PEG/POE alkyl ethers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/395—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins

- A61K31/435—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having six-membered rings with one nitrogen as the only ring hetero atom

- A61K31/4353—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having six-membered rings with one nitrogen as the only ring hetero atom ortho- or peri-condensed with heterocyclic ring systems

- A61K31/436—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having six-membered rings with one nitrogen as the only ring hetero atom ortho- or peri-condensed with heterocyclic ring systems the heterocyclic ring system containing a six-membered ring having oxygen as a ring hetero atom, e.g. rapamycin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0012—Galenical forms characterised by the site of application

- A61K9/0019—Injectable compositions; Intramuscular, intravenous, arterial, subcutaneous administration; Compositions to be administered through the skin in an invasive manner

- A61K9/0024—Solid, semi-solid or solidifying implants, which are implanted or injected in body tissue

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/06—Ointments; Bases therefor; Other semi-solid forms, e.g. creams, sticks, gels

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L31/00—Materials for other surgical articles, e.g. stents, stent-grafts, shunts, surgical drapes, guide wires, materials for adhesion prevention, occluding devices, surgical gloves, tissue fixation devices

- A61L31/04—Macromolecular materials

- A61L31/06—Macromolecular materials obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L31/00—Materials for other surgical articles, e.g. stents, stent-grafts, shunts, surgical drapes, guide wires, materials for adhesion prevention, occluding devices, surgical gloves, tissue fixation devices

- A61L31/14—Materials characterised by their function or physical properties, e.g. injectable or lubricating compositions, shape-memory materials, surface modified materials

- A61L31/145—Hydrogels or hydrocolloids

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L31/00—Materials for other surgical articles, e.g. stents, stent-grafts, shunts, surgical drapes, guide wires, materials for adhesion prevention, occluding devices, surgical gloves, tissue fixation devices

- A61L31/14—Materials characterised by their function or physical properties, e.g. injectable or lubricating compositions, shape-memory materials, surface modified materials

- A61L31/16—Biologically active materials, e.g. therapeutic substances

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2300/00—Biologically active materials used in bandages, wound dressings, absorbent pads or medical devices

- A61L2300/60—Biologically active materials used in bandages, wound dressings, absorbent pads or medical devices characterised by a special physical form

- A61L2300/602—Type of release, e.g. controlled, sustained, slow

Definitions

- rapamycin suffers from poor bioavailability and once-daily dosing results in fluctuating peak and trough blood levels.

- Immunosuppressive effectiveness of rapamycin and other limus compounds is dose dependent requiring that trough levels of drug remain in the therapeutic range. Too high blood levels of drug are linked to adverse and overtly toxic effects. It is desirable to maintain blood levels of drug within a therapeutic window.

- a drug delivery composition comprising a lipophilic agent and a polymer wherein the lipophilic agent exhibits sustained release and wherein there is less than 10% agent release within the first hour of elution.

- a drug delivery composition comprising a lipophilic agent and a polymer wherein the elution profile is substantially linear, and wherein there is less than 10% agent release within the first hour of elution.

- the elution profile is determined through in- vitro testing. In some embodiments, the elution profile is determined through in- vivo testing.

- sustained release comprises the lipophilic agent releasing over a period of > 3 hours, > 24 hours, > 1 week, > 3 months, > 6 months, and/or > 12 months. In some embodiments, there is less than 5% agent release within the first hour of elution. In some embodiments, no agent is delivered in the first hour of elution.

- the in-vitro elution profile exhibits no burst of elution in the first hour of elution, in the first 3 hours of elution, in the first 6 hours of elution, in the first 9 hours of elution, in the first 12 hours of elution, in the first 18 hours of elution, and/or in the first day of elution.

- the elution profile is substantially linear once a detectable amount of drug is eluted.

- a drug delivery composition comprising a lipophilic agent and a polymer wherein the PK profile varies only within 10% of an average PK profile for the composition.

- a drug delivery composition comprising a lipophilic agent and a polymer wherein the AUC (area under the curve which is the integral of the concentration-time curve after a single dose or in steady state) of the PK profile of the composition varies only within 10% of an average AUC for the composition.

- a drug delivery composition comprising a lipophilic agent and a polymer wherein the Cmax (which is the peak plasma concentration of a drug after administration) of the PK profile of the composition varies only within 10% of an average Cmax for the composition.

- a drug delivery composition comprising a lipophilic agent and a polymer wherein the Tmax (which is the time it takes to reach Cmax) of the PK profile varies only within 10% of an average Tmax for the composition.

- the PK profile of the composition is linear such that the linear regression fit to the in- vivo PK data has a R A 2 value of >0.8, or such that the linear regression fit to the in-vitro PK data has a R A 2 value of >0.8.

- the lipophilic agent comprises a limus drug, mTOR inhibitors, antibiotic agents, and/or immunosuppressive agents.

- the polymer comprises any one or more of a linear polymer, branched polymer, dendritic polymer, liquid crystalline polymer, amorphous polymer, semi-crystalline polymer, block co-polymer, tri-block copolymer, graft copolymer, polymer blend, ionomeric polymers, absorbable polymer, and bio-polymer.

- the polymer comprises a tri-block polymer with two hydrophilic chains connected by a hydrophobic chain.

- the polymer comprises a tri-block polymer with two hydrophobic chains connected by a hydrophilic chain.

- the polymer comprises a pluronic polymer.

- the pluronic polymer comprises a biocompatible reverse thermo sensitive polymer.

- the polymer comprises a poloxamer or a poloxamine, or a combination thereof.

- the polymer comprises poloxamer 407, poloxamer 338, poloxamer 1 18, poloxamine 1 107 or poloxamine 1307, or a combination thereof.

- the polymer comprises block copolymers, random copolymers, graft polymers, branched copolymers, or a combination thereof.

- the polymer comprises polyoxyalkylene block copolymer. In some embodiments, the polymer comprises at least one purified inverse thermo sensitive polymer selected from the group consisting of purified poloxamers and purified poloxamines. In some embodiments, the composition has a transition temperature of between about 10 °C and about 40 °C. In some embodiments, the composition has a transition temperature of between about 15 °C and about 30 °C. In some embodiments, the volume of said composition at physiological temperature is about 80% to about 120% of its volume below its transition temperature. In some embodiments, the volume of said composition at physiological temperature is about 80%> to about 120% of its volume below its transition temperature; and said composition has a transition temperature of between about 10 °C and about 40 °C. In some embodiments, the volume of said composition at

- physiological temperature is about 80%> to about 120% of its volume below its transition temperature; and said composition has a transition temperature of between about 15 °C and about 30 °C.

- the volume of said composition at physiological temperature is about 80% to about 120% of its volume below its transition temperature; said composition has a transition temperature of between about 10 °C and about 40 °C; and said composition comprises at least one purified inverse thermo sensitive polymer selected from the group consisting of poloxamers and poloxamines.

- the volume of said composition at physiological temperature is about 80%> to about 120% of its volume below its transition temperature; and said composition has a transition temperature of between about 15 °C and about 30 °C.

- the volume of said composition at physiological temperature is about 80% to about 120% of its volume below its transition temperature; said composition has a transition temperature of between about 10 °C and about 40 °C; and said composition comprises at least one purified inverse thermo sensitive polymer selected from the group consisting of poloxamers and poloxamines.

- physiological temperature is about 80% to about 120% of its volume below its transition temperature; said composition has a transition temperature of between about 15 °C and about 30 °C; and said composition comprises at least one purified inverse thermo sensitive polymer selected from the group consisting of poloxamers and poloxamines. In some embodiments, the composition comprises about 50%> to about 35% of said inverse thermo sensitive polymer. In some

- the composition comprises about 5% to about 30% of said inverse thermo sensitive polymer.

- the inverse thermo sensitive polymer has a polydispersity index from about 1.5 to about 1.0.

- the inverse thermo sensitive polymer has a polydispersity index from about 1.2 to about 1.0.

- the composition is a gel at a first temperature and a liquid at a second temperature, wherein the second temperature is lower than the first temperature.

- the composition is a gel at body temperature.

- the first temperature is at most 5 °C higher, 3 °C higher, at most 2 °C higher, at most 1 °C higher, at most 0.5 °C higher, at most 0.3 °C higher, or at most 0.2 °C higher than the second temperature.

- the composition at physiological conditions after 24 hours contains > 5% aqueous mass.

- the composition has a sol (water) fraction of a hydrogel at physiological conditions after 24 hours.

- the sol fraction is the fractional increase in the weight of the composition due to water absorption.

- the composition is a hydrogel and/or has hydrogel properties.

- at least a portion of the lipophilic agent is crystalline or semi-crystalline.

- the composition is formulated for use in, treatment of, or diagnosis of: chronic diseases; cancer;

- the composition is incorporated into a system comprising a substrate that carries the composition to the administration site or delivery site or treatment site.

- the substrate comprises a medical implant, diagnostic device, interventional device, and/or surgical tool.

- the substrate is a device, tool, or implant for use in orthopedics, neurology, cardiology, vascular treatment or diagnosis, opthamology, urology, gastroenterology, gynecology, obstetrics, aesthetic treatments or diagnosis, surgical applications such as for wound closure, healing, anti-infection, at least; dental ailments, conditions, disorders, or diseases such as periodontal disease; anti-viral treatment regimens such as HIV and hepatitis treatment or diagnosis; vaccines; and/or aesthetic applications.

- the substrate is a device, tool, or implant for use in allergy and immunology, anesthesiology, critical care medicine, hospice and palliative medicine, pain medicine, sleep medicine, colon and rectal surgery, dermatology, dermatopathology, emergency medicine, critical care medicine, emergency medical services, medical toxicology, sports medicine, undersea and hyperbaric medicine, family medicine, Internal medicine, cardiology, Interventional cardiology electrophysiology, endocrinology, diabetes, metabolism, gastroenterology, geriatric medicine, hematology, Infectious disease, oncology, nephrology, pulmonary disease,

- rheumatology hepatology, transplant hepatology, genetics, cytogenetics, molecular genetics, neurological surgery, neurology, nuclear medicine, obstetrics, gynecology, reconstructive surgery, maternal and fetal medicine, reproductive endocrinology, endocrinology, reproductive Infertility, orthopedic surgery, orthopedics, otolaryngology, neurotology, plastic surgery, pathology, blood banking/ transfusion medicine, cytopathology, dermatopathology, neuropathology, pediatrics, neonatal-Perinatal medicine, neurodevelopmental disabilities, hematology, pulmology,

- a drug delivery composition comprising a biological agent and a polymer wherein the biological agent exhibits sustained release and wherein there is less than 10% agent release within the first hour of elution.

- a drug delivery composition comprising a biological agent and a polymer wherein the elution profile is substantially linear, and wherein there is less than 10% agent release within the first hour of elution.

- the elution profile is determined through in-vitro testing. In some embodiments, the elution profile is determined through in- vivo testing. In some embodiments, sustained release comprises the biological agent releasing over a period of > 3 hours, > 24 hours, > 1 week, > 3 months, > 6 months, and/or > 12 months. In some embodiments, there is less than 5% agent release within the first hour of elution. In some embodiments, no agent is delivered in the first hour of elution.

- the in-vitro elution profile exhibits no burst of elution in the first hour of elution, in the first 3 hours of elution, in the first 6 hours of elution, in the first 9 hours of elution, in the first 12 hours of elution, in the first 18 hours of elution, and/or in the first day of elution.

- the elution profile is substantially linear once a detectable amount of agent is eluted.

- a drug delivery composition comprising a biological agent and a polymer wherein the PK profile varies only within 10% of an average PK profile for the composition.

- a drug delivery composition comprising a biological agent and a polymer wherein the AUC (area under the curve which is the integral of the concentration-time curve after a single dose or in steady state) of the PK profile of the composition varies only within 10% of an average AUC for the composition.

- a drug delivery composition comprising a biological agent and a polymer wherein the Cmax (which is the peak plasma concentration of a drug after administration) of the PK profile of the composition varies only within 10% of an average Cmax for the composition.

- a drug delivery composition comprising a biological agent and a polymer wherein the Tmax (which is the time it takes to reach Cmax) of the PK profile varies only within 10% of an average Tmax for the composition.

- the PK profile of the composition is linear such that the linear regression fit to the in- vivo PK data has a R A 2 value of >0.8, or such that the linear regression fit to the in-vitro PK data has a Pv A 2 value of >0.8.

- the biological agent comprises peptides, proteins, enzymes, derivatives and analogs of natural peptides, proteins and enzymes, glycoproteins, nucleic acids (including deoxyribonucleotide or ribonucleotide polymers in either single or double stranded form, and unless otherwise limited, encompasses known analogues of natural nucleotides that hybridize to nucleic acids in a manner similar to naturally occurring nucleotides), antisense nucleic acids, fatty acids, antimicrobials, vitamins, hormones, steroids, lipids, polysaccharides,

- the composition is a gel at a first temperature and a liquid at a second temperature, wherein the second temperature is lower than the first temperature.

- the first temperature is at most 5 °C higher, 3 °C higher, at most 2 °C higher, at most 1 °C higher, at most 0.5 °C higher, at most 0.3 °C higher, or at most 0.2 °C higher than the second temperature.

- the composition is a gel at body temperature.

- the polymer comprises any one or more of a linear polymer, branched polymer, dendritic polymer, liquid crystalline polymer, amorphous polymer, semi-crystalline polymer, block co-polymer, tri-block copolymer, graft copolymer, polymer blend, ionomeric polymers, absorbable polymer, and bio-polymer.

- the polymer comprises a tri-block polymer with two hydrophilic chains connected by a hydrophobic chain.

- the polymer comprises a tri-block polymer with two hydrophobic chains connected by a hydrophilic chain.

- the polymer comprises a pluronic polymer.

- the pluronic polymer comprises a biocompatible reverse thermo sensitive polymer.

- the polymer comprises a poloxamer or a poloxamine, or a combination thereof.

- the polymer comprises poloxamer 407, poloxamer 338, poloxamer 1 18, poloxamine 1 107 or poloxamine 1307, or a combination thereof.

- the polymer comprises block copolymers, random copolymers, graft polymers, branched copolymers, or a combination thereof.

- the polymer comprises polyoxyalkylene block copolymer.

- the polymer comprises at least one purified inverse thermo sensitive polymer selected from the group consisting of purified poloxamers and purified poloxamines.

- the composition has a transition temperature of between about 10 °C and about 40 °C. In some embodiments, the composition has a transition temperature of between about 15 °C and about 30 °C. In some embodiments, the volume of said composition at physiological temperature is about 80% to about 120% of its volume below its transition temperature. In some embodiments, the volume of said composition at physiological temperature is about 80% to about 120% of its volume below its transition temperature; and said composition has a transition temperature of between about 10 °C and about 40 °C.

- the volume of said composition at physiological temperature is about 80% to about 120% of its volume below its transition temperature; and said composition has a transition temperature of between about 15 °C and about 30 °C. In some embodiments, the volume of said composition at physiological temperature is about 80%> to about 120% of its volume below its transition temperature; said composition has a transition temperature of between about 10 °C and about 40 °C; and said composition comprises at least one purified inverse thermo sensitive polymer selected from the group consisting of poloxamers and poloxamines.

- the volume of said composition at physiological temperature is about 80%> to about 120%) of its volume below its transition temperature; said composition has a transition temperature of between about 15 °C and about 30 °C; and said composition comprises at least one purified inverse thermo sensitive polymer selected from the group consisting of poloxamers and poloxamines.

- the composition comprises about 50%> to about 35%> of said inverse thermo sensitive polymer.

- the composition comprises about 5%> to about 30%> of said inverse

- thermo sensitive polymer In some embodiments, the inverse thermo sensitive polymer has a polydispersity index from about 1.5 to about 1.0. In some embodiments, the inverse

- thermo sensitive polymer has a polydispersity index from about 1.2 to about 1.0.

- the composition at physiological conditions after 24 hours contains > 5% aqueous mass.

- the composition has a sol (water) fraction of a hydrogel at physiological conditions after 24 hours.

- the sol fraction is the fractional increase in the weight of the composition due to water absorption.

- the composition is a hydrogel and/or has hydrogel properties.

- the biological agent is in an active form, wherein active form comprises having a degree of secondary, tertiary and/or quaternary structure upon which the activity of the agent depends.

- the composition is formulated for use in, treatment of, or diagnosis of: chronic diseases; cancer; neurologic ailments, conditions, disorders, or diseases; pain, reproductive ailments, conditions, disorders, or diseases, or as part of a reproductive therapies or treatment; opthamalogic ailments, conditions, disorders, or diseases; GI ailments, conditions, disorders, or diseases; orthopedic ailments, conditions, disorders, or diseases; surgical applications such as for wound closure, healing, anti-infection, at least; dental ailments, conditions, disorders, or diseases such as periodontal disease; anti-viral treatment regimens such as HIV and hepatitis treatment or diagnosis; vaccines; and/or aesthetic applications.

- the composition is incorporated into a system comprising a substrate that carries the composition to the administration site or delivery site or treatment site.

- the substrate comprises a medical implant, diagnostic device, interventional device, and/or surgical tool.

- the substrate is a device, tool, or implant for use in orthopedics, neurology, cardiology, vascular treatment or diagnosis, opthamology, urology, gastroenterology, gynecology, obstetrics, aesthetic treatments or diagnosis, surgical applications such as for wound closure, healing, anti-infection, at least; dental ailments, conditions, disorders, or diseases such as periodontal disease; anti- viral treatment regimens such as HIV and hepatitis treatment or diagnosis; vaccines; and/or aesthetic applications.

- the substrate is a device, tool, or implant for use in allergy and immunology, anesthesiology, critical care medicine, hospice and palliative medicine, pain medicine, sleep medicine, colon and rectal surgery, dermatology, dermatopathology, emergency medicine, critical care medicine, emergency medical services, medical toxicology, sports medicine, undersea and hyperbaric medicine, family medicine, Internal medicine, cardiology, Interventional cardiology electrophysiology, endocrinology, diabetes, metabolism, gastroenterology, geriatric medicine, hematology, Infectious disease, oncology, nephrology, pulmonary disease, rheumatology, hepatology, transplant hepatology, genetics, cytogenetics, molecular genetics, neurological surgery, neurology, nuclear medicine, obstetrics, gynecology, reconstructive surgery, maternal and fetal medicine, reproductive endocrinology, endocrinology, reproductive Infertility, orthopedic surgery, orthopedics, otolaryngology, neuro

- a drug delivery composition comprising a lipophilic agent and a polymer, wherein said composition is a hydrogel, wherein the lipophilic agent exhibits sustained release, and wherein there is less than 35% lipophilic agent release within the first hour of elution.

- a drug delivery composition comprising a lipophilic agent and a polymer, wherein said composition is a hydrogel, wherein the elution profile is substantially linear, and wherein there is less than 35% lipophilic agent release within the first hour of elution.

- the elution profile is determined through in-vitro testing. In some embodiments, the elution profile is determined through in- vivo testing. In some embodiments, sustained release comprises the lipophilic agent releasing over a period of > 24 hours, > 3 days, > 1 week, > 10 days, or 16 days. In some embodiments, there is less than 10% agent release within the first hour of elution. In some embodiments, no agent is delivered in the first hour of elution.

- the in-vitro elution profile exhibits no burst of elution in the first hour of elution, in the first 3 hours of elution, in the first 6 hours of elution, in the first 9 hours of elution, in the first 12 hours of elution, in the first 18 hours of elution, and/or in the first day of elution.

- the elution profile is substantially linear once a detectable amount of drug is eluted.

- the lipophilic agent comprises a limus drug, mTOR inhibitors, antibiotic agents, and/or

- the lipophilic agent comprises a limus drug selected from rapamycin, bio limus (bio limus A9), 40-O-(2-Hydroxyethyl)rapamycin (everolimus), 40-O-Benzyl-rapamycin, 40-O-(4'-Hydroxymethyl)benzyl-rapamycin, 40-O-[4'-(l ,2- Dihydroxyethyl)]benzyl-rapamycin, 40-O-Allyl-rapamycin, 40-O-[3'-(2,2-Dimethyl- 1 ,3-dioxolan- 4(S)-yl)-prop-2'-en- 1 '-yl] -rapamycin, (2':E,4'S)-40-O-(4',5'-Dihydroxypent-2'-en- 1 '-yl)-rapamycin, 40-O-(2-Hydroxy)ethoxycar

- the lipophilic agent is rapamycin.

- the polymer comprises any one or more of a linear polymer, branched polymer, dendritic polymer, liquid crystalline polymer, amorphous polymer, semi- crystalline polymer, block co-polymer, tri- block copolymer, graft copolymer, polymer blend, ionomeric polymers, absorbable polymer, and bio-polymer.

- at least a portion of the lipophilic agent is crystalline or semi- crystalline. In some embodiments, at least 50%, 60%, 70%, 75%, 80%, 85%, 90%, 92%, 95%, 98%o, 99%), 99.0%), 99.5%), or 99% of the lipophilic agent in the composition is in crystalline or semi-crystalline form.

- a drug delivery composition formulated for use in, treatment of, or diagnosis of: chronic diseases; cancer; neurologic ailments, conditions, disorders, or diseases; pain, reproductive ailments, conditions, disorders, or diseases, or as part of a reproductive therapies or treatment; opthamalogic ailments, conditions, disorders, or diseases; GI ailments, conditions, disorders, or diseases; orthopedic ailments, conditions, disorders, or diseases; surgical applications such as for wound closure, healing, anti-infection, at least; dental ailments, conditions, disorders, or diseases such as periodontal disease; anti-viral treatment regimens such as HIV and hepatitis treatment or diagnosis; vaccines; and/or aesthetic applications.

- composition in some embodiments is a drug delivery composition wherein the composition is incorporated into a system comprising a substrate that carries the composition to the administration site or delivery site or treatment site.

- substrate comprises a medical implant, diagnostic device, interventional device, and/or surgical tool.

- the substrate is a device, tool, or implant for use in orthopedics, neurology, cardiology, vascular treatment or diagnosis, opthamology, urology, gastroenterology, gynecology, obstetrics, aesthetic treatments or diagnosis, surgical applications such as for wound closure, healing, anti-infection, at least; dental ailments, conditions, disorders, or diseases such as periodontal disease; anti- viral treatment regimens such as HIV and hepatitis treatment or diagnosis; vaccines; and/or aesthetic applications.

- the substrate is a device, tool, or implant for use in allergy and immunology, anesthesiology, critical care medicine, hospice and palliative medicine, pain medicine, sleep medicine, colon and rectal surgery, dermatology, dermatopathology, emergency medicine, critical care medicine, emergency medical services, medical toxicology, sports medicine, undersea and hyperbaric medicine, family medicine, Internal medicine, cardiology, Interventional cardiology electrophysiology, endocrinology, diabetes, metabolism, gastroenterology, geriatric medicine, hematology, Infectious disease, oncology, nephrology, pulmonary disease, rheumatology, hepatology, transplant hepatology, genetics, cytogenetics, molecular genetics, neurological surgery, neurology, nuclear medicine, obstetrics, gynecology, reconstructive surgery, maternal and fetal medicine, reproductive endocrinology, endocrinology, reproductive Infertility, orthopedic surgery, orthopedics, otolaryngology, neuro

- FIG. 1 A shows the cumulative fraction release of of rapamycin from three hydrogel compositions prepared in Example 1.

- Fig. IB depicts the cumulative mass release of of rapamycin from three hydrogel compositions prepared in Example 1 using the zero order model.

- Fig. 2 depicts the log cumulative percent release of of rapamycin from three hydrogel compositions prepared in Example 1 using the Korsmeyer-Peppas model.

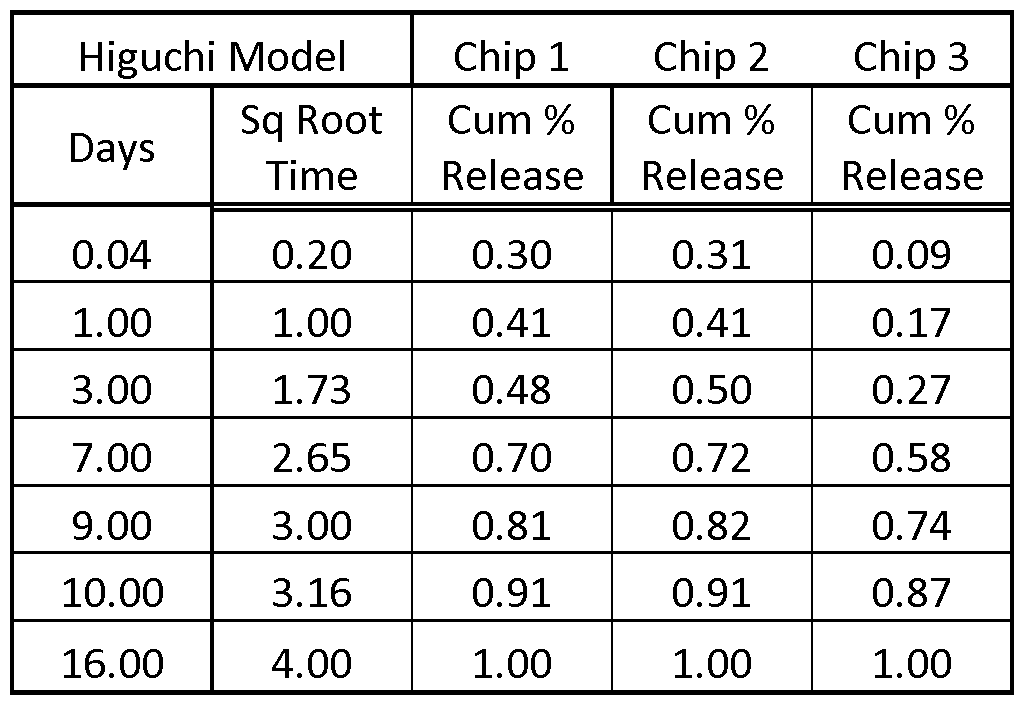

- FIG. 3 depicts the cumulative fraction release of of rapamycin from three hydrogel compositions prepared in Example 1 using the Higuchi model.

- drug delivery composition refers to a composition capable of delivering a drug when administered to a subject independently of a substrate such as a stent or other medical device coated with the composition. Once the composition is administered to the subject, the composition is separated from the device used to administer the composition (e.g., a syringe) and drug delivery is carried out by the drug delivery composition without the need for a substrate. It should be noted that embodiments decribed herein and claimed below when reference is not made to “drug delivery composition” include compositions that are delivered as part of a device such as a transdermal delivery device.

- Examples of pharmaceutical agents employed in conjunction with the invention include, rapamycin, biolimus (biolimus A9), 40-O-(2-Hydroxyethyl)rapamycin (everolimus), 40-O-Benzyl- rapamycin, 40-O-(4'-Hydroxymethyl)benzyl-rapamycin, 40-O-[4'-(l ,2-Dihydroxyethyl)]benzyl- rapamycin, 40-O-Allyl-rapamycin, 40-O-[3'-(2,2-Dimethyl- 1 ,3-dioxolan-4(S)-yl)-prop-2'-en- 1 -yl]- rapamycin, (2':E,4'S)-40-O-(4',5'-Dihydroxypent-2'-en-r-yl)-rapamycin, 40-O-(2- Hydroxy)ethoxycar-bonylmethyl-rapamycin, 40-O-(

- the pharmaceutical agents may, if desired, also be used in the form of their

- pharmaceutical agent may include a prodrug, a hydrate, an ester, a polymorph, a derivative or analogs of a compound or molecule.

- the pharmaceutical agent may be an antibiotic agent, as described herein.

- Prodrugs are derivative compounds derivatized by the addition of a group that endows greater solubility to the compound desired to be delivered. Once in the body, the prodrug is typically acted upon by an enzyme, e.g., an esterase, amidase, or phosphatase, to generate the active compound.

- an enzyme e.g., an esterase, amidase, or phosphatase

- an "anti-cancer agent”, “anti-tumor agent” or “chemotherapeutic agent” refers to any agent useful in the treatment of a neoplastic condition. There are many chemotherapeutic agents available in commercial use, in clinical evaluation and in pre-clinical development that are useful in the devices and methods of the present invention for treatment of cancers.

- Active agent as used herein comprises any therapeutic agent including a pharmaceutical agent which may be lipophilic agent as described herein or a biologic agent as described herein.

- a "lipophilic agent” or “lipophilic compound” as used herein include poorly water soluble pharmaceutical agents. Lipophilic agents tend to combine with or dissolve in lipids or fats. In some embodiments, lipophilic agents may also be hydrophobic. In other embodiments, the lipophilic agent may not be hydrophobic. The lipophilic agents may be only partially lipophilic, meaning that, for example, only a portion of the agents has lipophilic properties, or that the agent has some lipophilic properties, but also may exhibit other properties such as hydrophilicity, or that the agent has a low degree of lipophilicity. The agents referred to herein as lipophilic agents have a hydrophilic- lipophilic balance (HLB) of less than 10, 6 or less, or less than 6, and fall within the HLB International scale, which ranges from 0-20.

- HLB hydrophilic- lipophilic balance

- Lipophilic agents comprise, for non-limiting example: anticancer agents, immunosuppressive agents, corticoids, analgesics, human-immunodeficiency-virus protease inhibitors, antibiotic agents, or combinations thereof.

- Lipophilic anti-cancer agents comprise, for non-limiting example: doxorubicin, daunorubicin, idarubicin, vinblastine, vincristine, etoposide, methotrexate, or combinations thereof.

- Lipophilic corticoids comprise, for non-limiting example: dexamethasone, hydrocortisone, or combinations thereof.

- Lipophilic analgesics comprise, for non-limiting example:

- Human-immunodeficiency- virus protease inhibitors comprise, for non-limiting example: amprenavir, saquinavir, ritonavir, or combinations thereof.

- Farglitazar for example, is partly lipophilic and partly hydrophilic, and may be considered a lipophilic agent herein, as would other therapeutic or biological agents that are partly lipophilic. Other agents may be used as noted elsewhere herein, or as known to one of skill in the art, so long the agent demonstrates lipophilic properties (e.g. HLB of less than 10).

- Lipophilic agents may comprise antibiotic agents or macrolide antibiotics such as: antierythromycin base and its pharmaceutically acceptable salts and esters, as well as the semisynthetic derivatives of erythromycin, including but not limited to 6-O-methyl- erythromycin (clarithromycin), the erythromycin 9-oximes, erythromycin 11, 12-cyclic carbamates and 4"-deoxy-l l, 12 carbamates, 1-0— methyl-, and 6, 11-di-O-methyl erythromycins, 8- fluoroethyromycin, erythromycin 4"-carbamates, and compounds having various combinations of these structural modifications, as well as their pharmaceutically acceptable salts and esters.

- antibiotic agents or macrolide antibiotics such as: antierythromycin base and its pharmaceutically acceptable salts and esters, as well as the semisynthetic derivatives of erythromycin, including but not limited to 6-O-methyl- erythromycin (clarithromycin), the erythromycin 9-oximes, ery

- Immunosuppressive agents are used. Immunosuppressive agents may also be referred to as immunosupressants or immunosuppressive drugs or immunomodulators or immunomodulating drugs. Such immunosuppressive agents may include a cyclosporine, or ascomycine or their immunosuppressive analogs or derivatives, e.g. cyclosporin A, cyclosporin G, FK-506, ABT-281, ASM 981; an mTOR inhibitor, e.g. rapamycin, 40-O-(2-hydroxy)ethyl- rapamycin.

- Example immunosupressants include, but are not limited to: antimetabolites such as purine synthesis inhibitors (e.g.

- azathioprine mycophenolic acid

- pyrimidine synthesis inhibitors e.g. leflunomide and teriflunomide

- antifolate e.g. methotrexate

- macro lides or other IL-2 inhibitors such as FKBP/ cyclopholin/ calcineurin (e.g. tacrolimus, ciclosporin, pimecrolims, abetimus or gusperimus); or TNF inhibitors such as thalidomide or lenalidomide.

- immunosupressants include, but are not limited to: IL-1 receptor antagonists such as anakinra, or mTOR inhibitors (sirolimus, everolimus, ridaforolimus, temserolimus, umirolimus, zotarolims).

- IL-1 receptor antagonists such as anakinra, or mTOR inhibitors (sirolimus, everolimus, ridaforolimus, temserolimus, umirolimus, zotarolims).

- immunosupressants include, but are not limited to: monoclonoal antibodies having a non-cellular serum target such as: complement component 5 (Eculizumab), TNFs (Infliximab, Adalimumab, Certolizumab pegol, Afelimomab, Golimumab), Interleukin 5 (Mepolizumab), Immunoglobulin E (Omalizumab), BAYX (Nerelimomab), Interferon (Faralimomab), IL-6

- immunosupressants include, but are not limited to: monoclonoal antibodies having a cellular target such as: CD3 (Muromonab-CD3, Otelixizumab, Teplizumab, Visilizumab), CD4 (Clenoliximab, Keliximab, Zanolimumab), CDl la (Efalizumab), CD 18 (Erlizumab), CD20 (Afutuzumab,

- Tremelimumab Tremelimumab

- CAT Bactilimumab, Lerdelimumab, Metelimumab

- Integrin Neatalizumab

- Interleukin-6 receptor Tocilizumab

- LFA-1 Optilimomab

- IL-2 receptor/CD25 Basiliximab, Daclizumab, Inolimomab

- T-lymphocyte Zolimomab aritox

- immunosupressants include, but are not limited to: monoclonal antibodies (unsorted target) such as: Atorolimumab, Cedelizumab, Fontolizumab, Maslimomab, Morolimumab, Pexelizumab,

- Reslizumab Reslizumab, Rovelizumab, Siplizumab, Talizumab, Telimomab aritox, Vapaliximab, or

- Vepalimomab Vepalimomab.

- Other example immunosupressants include, but are not limited to: polyclonal antibodies such as Anti-thymocyte globulin, or Anti-lymphocyte globulin.

- Other example immunosupressants include, but are not limited to: CTLA-4 (Abatacept, Belatacept), TNF inhibitor, (Etanercept, Pegsunercept), Aflibercept, Alefacept, or Rilonacept.

- mTOR inhibitor as used herein includes, but is not limited to rapamycin (sirolimus) or a salt, prodrug, ester, or derivative thereof.

- Rapamycin is a known macrolide antibiotic, also known as Sirolimus & Rapamune is an mTOR inhibitor. Rapamycin inhibits cell motility by suppression of mTOR-mediated pathways.

- mTOR inhibitors such as rapamycin and its analogs are lipophilic. Rapamycin and it's analogs (or rapalogues e.g. CCI-779) modulate the phosphatidylinositol 3- kinase (PI3K) signalling cascade by binding to an allosteric site on the mTORCl complex.

- PI3K phosphatidylinositol 3- kinase

- mTOR Mammalian target of rapamycin (mTOR), a class IV PI3K protein kinase, forms two functional complexes, mTORCl and mTORC2.

- mTOR plays a major role in regulating cell growth and proliferation and it's aberrant function is implicated in a number of cancers.

- Suitable derivatives may include those disclosed in WO94/09010, W096/16691,

- rapamycin derivatives include 32-deoxorapamycin, 16-pent-2-ynyloxy-32-deoxorapamycin, 16- pent-2-ynyloxy-32(S)-dihydro-rapamycin, 16-pent-2-ynyloxy-32(S)-dihydro-40-O-(2- hydroxyethyl)-rapamycin and, more preferably, 40-O-(2-hydroxyethyl)rapamycin.

- Further examples of rapamycin derivatives include e.g.

- an mTOR inhibitor includes BEZ235 (NVP-BEZ235) which is a dual ATP-competitive phosphatidylinositol 3-kinase (PI3K) and mammalian target of rapamycin (mTOR) inhibitor of pi 10a, pi 10 ⁇ , pi 105 and pi 10 ⁇ with IC50 of 4 nM, 5 nM, 7 nM and 75 nM, respectively.

- BEZ235 NBP-BEZ235

- mTOR mammalian target of rapamycin

- mTOR inhibitor includes Everolimus (RADOOl), also known as SDZ-RAD, Certican, Zortress and Afinitorm, and is an mTOR inhibitor with IC50 of 0.63 nM.

- an mTOR inhibitor includes PI- 103 is a potent, cell-permeable, ATP-competitive PI3K family member inhibitor with IC50 of 2, 8, 20, 26, 48, 83, 88, 150 nM for DNA-PK, pi 10a, mTORCl, PB-KC2P, ⁇ ⁇ , mTORC2, ⁇ ⁇ , and pi 10 ⁇ , respectively.

- Another example of an mTOR inhibitor includes Temsirolimus (Torisel).

- AZD8055 is a potent, selective, and orally bioavailable ATP-competitive mTOR kinase inhibitor with an IC50 of 0.8 nM.

- an mTOR inhibitor includes AZD8055 is a potent, selective, and orally bioavailable ATP-competitive mTOR kinase inhibitor with an IC50 of 0.8 nM.

- Another example of an mTOR inhibitor includes Ku-0063794 is an mTOR inhibitor, IC50 ⁇ 10 nM for mTORCl and mTORC2, respectively.

- Another example of an mTOR inhibitor includes NVP- BGT226 is a novel dual PI3K/mTOR inhibitor with an IC50 of 1 nM.

- an mTOR inhibitor includes PF-04691502 is a potent and selective dual PI3K/mTOR inhibitor to phosphorylation of AKT T308 and AKT S473 with IC50 of 7.5 and 3.8 nM, respectively.

- Another example of an mTOR inhibitor includes CH5132799 is a novel and selective class I PI3K inhibitor with IC50 of 0.014, 0.12, 0.5, 0.036, 5.3 and 1.6 ⁇ for ⁇ , ⁇ , ⁇ , ⁇ , ⁇ C2p and mTOR, respectively.

- an mTOR inhibitor includes GDC-0980 (RG7422) is a selective, dual PB Kinase and mTOR inhibitor with IC50 of 5, 27, 7, and 14 nM for ⁇ , ⁇ , ⁇ , and ⁇ , respectively.

- Another example of an mTOR inhibitor includes WAY-600 is a potent ATP- competitive mTOR inhibitor with an IC50 of 9 nM.

- Another example of an mTOR inhibitor includes WYE- 125132 is a highly potent, ATP-competitive and specific mTOR kinase inhibitor with an IC50 of 0.19 nM.

- an mTOR inhibitor includes WYE-687 is a potent ATP-competitive mTOR inhibitor with an IC50 of 7 nM.

- Another example of an mTOR inhibitor includes GSK2126458 is a highly potent PBK and mTOR inhibitor with an app Ki of 19 pM for PI3K.

- Another example of an mTOR inhibitor includes PKI-587 is a highly potent dual PI3K/mTOR kinase inhibitor with IC50 of 0.4 nM and ⁇ 0.1 ⁇ for PI3K-a and mTOR, respectively.

- an mTOR inhibitor includes PP121 is a multitargeted dual receptor tyrosine kinases inhibitor with IC50 of 0.052, 1.4, 0.15, 1.1, 0.06, 0.0 land 0.002 ⁇ for pi 10a, pi 10 ⁇ , pi 105, pi 10 ⁇ , DNA-PK, mTOR and PDGFR,

- Another example of an mTOR inhibitor includes OSI027 is a potent mammalian target of rapamycin (mTOR) kinase inhibitor, respectively.

- Another example of an mTOR inhibitor includes Palomid 529 (P529) is a novel PBK/Akt/mTOR inhibitor with a GI50 of ⁇ 35 ⁇ in the NCI-60 cell lines panel.

- PP242 is a novel selective mTOR inhibitor with an IC50 of 8 nM.

- Another example of an mTOR inhibitor includes Chrysophanic acid (Chrysophanol) is a EGFR/mTOR pathway inhibitor.

- XL765 is a mixed mTOR/PBk inhibitor with IC50 of 157, 39, 113, 9 and 43 nM for mTOR, pi 10a, ⁇ , ⁇ and ⁇ , respectively.

- Another example of an mTOR inhibitor includes GSK1059615 is a pan-PBK reversible inhibitor,IC50:PI3Ka(0.4 nM), ⁇ (0.6 ⁇ ), ⁇ (5 ⁇ ), ⁇ (2 nM) and mTOR(12 nM).

- mTOR inhibitor includes WYE-354 is an mTOR inhibitor with an IC50 of 5 nM.

- Deforolimus (Ridaforolimus) is a small-molecule inhibitor of mTOR.

- '"limus drugs” or '"limus agents are macrolide immunosuppressive drugs. They include, for nonlimiting example, sirolimus, everolimus, biolimus A9, zotarolimus, tacrolimus and pimecrolimus. Sirolimus, everolimus, biolimus A9 (biolimus), and zotarolimus all bind to the FKBP12 binding protein, which subsequently binds to the mammalian target of rapamycin (mTOR) and thereby blocks the cell cycle mainly of the smooth muscle cell from the Gl to S phase. The mechanisms of action of tacrolimus and pimecrolimus are different. Both drugs bind to FKBP506. The tacrolimus/pimecro limus FKBP506 complex subsequently inhibits the calcineurin receptor, which leads to decreased cytokine expression on the cell surface membrane and results in an inhibition of T-cell activation and lower smooth muscle cell selectivity.

- mTOR mammalian target of rapamycin

- Sirolimus a natural macrocyclic lactone that is able to inhibit mTOR. Sirolimus possess potent antiproliferative and immunosuppressive effects.

- Everolimus is a sirolimus analog with a single minimal alteration in its molecular structure (position 40), without a chemical modification of the mTOR binding domain.

- Zotarolimus also has a change on position 40, and is known as ABT-578, Abbott

- zotarolimus is suggested to have higher tissue retention when delivery in a drug eluting stent as compared with the sirolimus eluting stent.

- Biolimus A9 is a highly lipophilic sirolimus analog that inhibits T cell and smooth muscle cell proliferation.

- pimecrolimus does not block mTOR and inhibits to a much lesser degree the endothelial cell proliferation.

- the active pharmaceutical ingredient of pimecrolimus is Elidel, an FDA-approved drug developed by Novartis Pharmaceuticals Corp, East Hanover, NJ) for the treatment of atopic dermatitis.

- pimecrolimus Although a part of the Limus family, pimecrolimus does not block mTOR and inhibits to a much lesser degree the endothelial cell proliferation.

- the active pharmaceutical ingredient of pimecrolimus is Elidel, an FDA-approved drug developed by Novartis Pharmaceuticals Corp, East Hanover, NJ) for the treatment of atopic dermatitis.

- Macrolide immunosuppressive (limus) drug or "macrolide immunosuppressive (limus) agent” may include, for non-limiting example: one or more of: rapamycin, bio limus (bio limus A9), 40-O-(2-Hydroxyethyl)rapamycin (everolimus), 40-O-Benzyl-rapamycin, 40-O-(4'- Hydroxymethyl)benzyl-rapamycin, 40-O-[4'-(l ,2-Dihydroxyethyl)]benzyl-rapamycin, 40-O-Allyl- rapamycin, 40-O-[3'-(2,2-Dimethyl-l,3-dioxolan-4(S)-yl)-prop-2'-en- -yl]-rapamycin, (2':E,4'S)- 40-O-(4',5'-Dihydroxypent-2'-en- 1 '-yl)-rapamycin

- Macrolide antibiotic drug or “macrolide antibiotic” may include, for non-limiting example: Azithromycin, Clarithromycin, Dirithromycin, Erythromycin, Roxithromycin,

- Telithromycin Carbomycin A, Josamycin, Kitasamycin, Midecamycin/midecamycin acetate, Oleandomycin, Solithromycin, Spiramycin, Troleandomycin, or Tylosin/tylocine, their

- esters pharmaceutically acceptable salts, esters, derivatives, isomers, racemates, diastereoisomers, prodrugs, hydrates, or analogs thereof.

- pharmaceutically acceptable salts and esters of macro lide antibiotics are the acetate, estolate (lauryl sulfate salt of the propionate ester), ethyl succinate, gluceptate (glucoheptonate), lactobionate, stearate, and hydrochloride forms.

- salts and esters or “salts” or “esters” as used herein can mean those salts and esters which are, within the scope of sound medical judqment, suitable for use in contact with the tissues of humans and lower animals without undue toxicity, irritation, allergic response, and the like, commensurate with a reasonable benefit/risk ratio, and effective for their intended use.

- acid salts used in the pharmaceutical arts are the following: adipate, alginate, aspartate, benzoate, benzene sulfonate, bisulfate, butyrate, citrate, camphorate, camphorsulfonate, cyclopentanepropionate, digluconate, dodecylsulfate, ethanesulfonate, fumarate, gluconate, glycerophosphate, hemisulfate, heptonate, hexanoate, hydrobromide, hydroiodide, 2-hydroxy ethanesulfonate, lactate, maleate, methanesulfonate, 2-naphthalenesulfonate, nicotinate, oxalate, pamoate, pantothenate, pectinate, persulfate, 3-phenylpropionate, picrate, pivalate, propionate, succinate, tartrate, thiocyanate, tosylate

- Basic nitrogen-containing groups can be quaternized with such agents as lower alkyl halides, such as methyl, ethyl, propyl and butyl chloride, bromides and iodides; dialkyl sulfates like dimethyl, diethyl, dibutyl, and diamyl sulfates; long chain halides such as decyl, lauryl, myristyl and stearyl chlorides, bromides and iodides;

- lower alkyl halides such as methyl, ethyl, propyl and butyl chloride, bromides and iodides

- dialkyl sulfates like dimethyl, diethyl, dibutyl, and diamyl sulfates

- long chain halides such as decyl, lauryl, myristyl and stearyl chlorides, bromides and iodides

- aralkyl halides like benzyl and phenethyl bromides and others. Water or oil-soluble or dispersible products are thereby obtained.

- the lipophilic agents may include: antiinfectives such as antibiotics and antiviral agents; analgesics and analgesic combinations; anorexics; antihelmintics; antiarthritics; antiasthmatic agents; anticonvulsants; antidepressants; antidiuretic agents; antidiarrheals; antihistamines;

- antiinfectives such as antibiotics and antiviral agents; analgesics and analgesic combinations; anorexics; antihelmintics; antiarthritics; antiasthmatic agents; anticonvulsants; antidepressants; antidiuretic agents; antidiarrheals; antihistamines;

- antiinflammatory agents include antimigraine preparations; antinauseants; antineoplastics;

- antiparkinsonism drugs include antipruritics; antipsychotics; antipyretics, antispasmodics; anticholinergics; sympathomimetics; xanthine derivatives; cardiovascular preparations including calcium channel blockers and beta-blockers such as pindolol and antiarrhythmics; antihypertensives; diuretics;

- vasodilators including general coronary, peripheral and cerebral; central nervous system stimulants; cough and cold preparations, including decongestants; hormones such as estradiol and other steroids, including corticosteroids; hypnotics; immunosuppressives; muscle relaxants;

- Suitable pharmaceuticals for parenteral administration are well known as is exemplified by the Handbook on Injectable Drugs, 6.sup.th Edition, by Lawrence A. Trissel, American Society of Hospital Pharmacists, Bethesda, Md., 1990 (hereby incorporated by reference).

- compositions described herein may comprise biological agents rather than lipophilic agents or in addition to the lipophilic agent.

- biological agents may comprise, for non-limiting example: proteins, vaccines, peptides, polypeptides, polynucleotides, nucleoproteins,

- polysaccharides including glycoproteins, lipoproteins, horomones, sR A, etc., including synthetic and biologically engineered analogs thereof, whether or not the biological agents themselves have lipophilic properties.

- a "biological agent” or “active biological agent” as used herein refers to a substance, originally produced by living organisms, that can be used to prevent or treat a disease (meaning any treatment of a disease in a mammal, including preventing the disease, i.e. causing the clinical symptoms of the disease not to develop; inhibiting the disease, i.e. arresting the development of clinical symptoms; and/or relieving the disease, i.e. causing the regression of clinical symptoms). It is possible that the biological agents of the invention may also comprise two or more active biological agents or an active biological agent combined with a pharmaceutical agent, a stabilizing agent or chemical or biological entity.

- nucleic acid could be isolated form from a biological source, or prepared by traditional techniques, known to those skilled in the art of nucleic acid synthesis.

- nucleic acid may be further modified to contain non-naturally occurring moieties.

- Non-limiting examples of biological agents include peptides, proteins, enzymes, glycoproteins, nucleic acids (including deoxyribonucleotide or ribonucleotide polymers in either single or double stranded form, and unless otherwise limited, encompasses known analogues of natural nucleotides that hybridize to nucleic acids in a manner similar to naturally occurring nucleotides), antisense nucleic acids, fatty acids, antimicrobials, vitamins, hormones, steroids, lipids, polysaccharides, carbohydrates and the like.

- antirestenotic agents antidiabetics

- analgesics antiinflammatory agents, antirheumatics, antihypotensive agents, antihypertensive agents, psychoactive drugs, tranquilizers, antiemetics, muscle relaxants, glucocorticoids, agents for treating ulcerative colitis or Crohn's disease, antiallergics, antibiotics, antiepileptics, anticoagulants, antimycotics, antitussives, arteriosclerosis remedies, diuretics, proteins, peptides, enzymes, enzyme inhibitors, gout remedies, hormones and inhibitors thereof, cardiac glycosides, immunotherapeutic agents and cytokines, laxatives, lipid-lowering agents, migraine remedies, mineral products, otologicals, anti parkinson agents, thyroid therapeutic agents, spasmolytics, platelet aggregation inhibitors, vitamins, cytostatics and metastasis inhibitors, phytopharmaceuticals and

- the biological agent is a peptide, protein or enzyme, including derivatives and analogs of natural peptides, proteins and enzymes.

- the biological agent may also be a hormone, gene therapies, R A, siR A, and/or cellular therapies (for non-limiting example, stem cells or T-cells).

- Activity refers to the ability of a pharmaceutical or active biological agent to prevent or treat a disease (meaning any treatment of a disease in a mammal, including preventing the disease, i.e. causing the clinical symptoms of the disease not to develop; inhibiting the disease, i.e. arresting the development of clinical symptoms; and/or relieving the disease, i.e. causing the regression of clinical symptoms).

- a pharmaceutical or active biological agent should be of therapeutic or prophylactic value.

- Secondary, tertiary and quaternary structure as used herein are defined as follows.

- the active biological agents of the present invention will typically possess some degree of secondary, tertiary and/or quaternary structure, upon which the activity of the agent depends.

- proteins possess secondary, tertiary and quaternary structure.

- Secondary structure refers to the spatial arrangement of amino acid residues that are near one another in the linear sequence.

- the .alpha.-helix and the .beta.-strand are elements of secondary structure.

- Tertiary structure refers to the spatial arrangement of amino acid residues that are far apart in the linear sequence and to the pattern of disulfide bonds.

- Proteins containing more than one polypeptide chain exhibit an additional level of structural organization.

- Each polypeptide chain in such a protein is called a subunit.

- Quaternary structure refers to the spatial arrangement of subunits and the nature of their contacts.

- hemoglobin consists of two .alpha, and two .beta, chains. It is well known that protein function arises from its conformation or three dimensional arrangement of atoms (a stretched out polypeptide chain is devoid of activity).

- one aspect of the present invention is to manipulate active biological agents, while being careful to maintain their

- the drug delivery composition may be incorporated into a system comprising a substrate that carries the composition to the administration site or delivery site or treatment site.

- the substrate may remain with the composition upon administration (or upon delivery of the composition) and for any amount of time or indefinitely thereafter, or be removed upon administration (or upon delivery of the composition) leaving the composition at the administration site or delivery site or treatment site.

- Substrate refers to any surface upon which it is desirable to deposit a coating comprising a polymer and a pharmaceutical or biological agent, wherein the coating process does not substantially modify the morphology of the pharmaceutical agent or the activity of the biological agent.

- Biomedical implants are of interest for the present invention; however the present invention is not intended to be restricted to this class of substrates. Interventional devices are also of interest for the present invention; however the present invention is not intended to be restricted to this class of substrates. Diagnostic devices are also of interest for the present invention; however the present invention is not intended to be restricted to this class of substrates.

- Those of skill in the art will appreciate alternate substrates that could benefit from the coating process described herein, such as pharmaceutical tablet cores, as part of an assay apparatus or as

- a diagnostic kit e.g. a test strip

- Substrates contemplated herein include, for non-limiting example: medical implants, diagnostic devices, interventional devices, and/or surgical tools.

- Substrates contemplated herein include, for non-limiting example any device, tool, or implant for use in: orthopedics, neurology, cardiology, vascular treatment or diagnosis, opthamology, urology, gastroenterology, gynecology, obstetrics, aesthetic treatments or diagnosis, surgical applications such as for wound closure, healing, anti-infection, at least; dental ailments, conditions, disorders, or diseases such as periodontal disease; anti- viral treatment regimens such as HIV and hepatitis treatment or diagnosis; vaccines; and/or aesthetic applications.

- the substrate is a device, tool, or implant for use in allergy and immunology, anesthesiology, critical care medicine, hospice and palliative medicine, pain medicine, sleep medicine, colon and rectal surgery, dermatology, dermatopathology, emergency medicine, critical care medicine, emergency medical services, medical toxicology, sports medicine, undersea and hyperbaric medicine, family medicine, Internal medicine, cardiology, Interventional cardiology electrophysiology, endocrinology, diabetes, metabolism, gastroenterology, geriatric medicine, hematology, Infectious disease, oncology, nephrology, pulmonary disease,

- rheumatology hepatology, transplant hepatology, genetics, cytogenetics, molecular genetics, neurological surgery, neurology, nuclear medicine, obstetrics, gynecology, reconstructive surgery, maternal and fetal medicine, reproductive endocrinology, endocrinology, reproductive Infertility, orthopedic surgery, orthopedics, otolaryngology, neurotology, plastic surgery, pathology, blood banking/ transfusion medicine, cytopathology, dermatopathology, neuropathology, pediatrics, neonatal-Perinatal medicine, neurodevelopmental disabilities, hematology, pulmology,

- rheumatology aerospace medicine, occupational medicine, psychiatry, brain injury medicine, neurophysiology, epilepsy, neuromuscular medicine, neuroradiology, nuclear radiology, radiation oncology, medical physics, vascular and Interventional radiology, surgery, vascular surgery, thoracic and cardiac surgery, and urology.

- a "Biomedical implant” as used herein refers to any implant for insertion into the body of a human or animal subject, including but not limited to stents (e.g., coronary stents, vascular stents including peripheral stents and graft stents, urinary tract stents, urethral prostatic stents, rectal stent, oesophageal stent, biliary stent, pancreatic stent), electrodes, catheters, leads, implantable pacemaker, cardioverter or defibrillator housings, joints, screws, rods, ophthalmic implants, femoral pins, bone plates, grafts, anastomotic devices, perivascular wraps, sutures, staples, shunts for hydrocephalus, dialysis grafts, colostomy bag attachment devices, ear drainage tubes, leads for pace makers and implantable cardioverters and defibrillators, vertebral

- the substrate is selected from the group consisting of: stents, joints, screws, rods, pins, plates, staples, shunts, clamps, clips, sutures, suture anchors, electrodes, catheters, leads, grafts, dressings, pacemakers, pacemaker housings, cardioverters, cardioverter housings, defibrillators, defibrillator housings, prostheses, ear drainage tubes, ophthalmic implants, orthopedic devices, vertebral disks, bone substitutes, anastomotic devices, perivascular wraps, colostomy bag attachment devices, hemostatic barriers, vascular implants, vascular supports, tissue adhesives, tissue sealants, tissue scaffolds and intraluminal devices.

- the implant may be temporarily used in or permanently implanted in the body of a human or animal subject.

- the implant may only be used in a transient manner in or on the body of the subject, for non-limiting example: during a medical procedure that does not leave the implant in or on the subject once the medical procedure is completed.

- the susbtrate may be formed from any suitable material, including but not limited to polymers (including stable or inert polymers, organic polymers, organic-inorganic copolymers, inorganic polymers, and biodegradable polymers), metals, metal alloys, inorganic materials such as silicon, and composites thereof, including layered structures with a core of one material and one or more coatings of a different material.

- Substrates may be made of a conducting material facilitate electrostatic capture.

- the invention contemplates the use of electrostatic capture, as described below, in conjunction with substrate having low conductivity or which are non- conductive. To enhance electrostatic capture when a non-conductive substrate is employed, the substrate is processed for example while maintaining a strong electrical field in the vicinity of the substrate.

- the susbtrate comprises a stainless steel material.

- the substrate comprises a material comprising a cobalt chromium alloy.

- the substrate comprises a material comprising the following percentages by weight: about 0.05 to about 0.15 C, about 1.00 to about 2.00 Mn, about 0.04 Si, about 0.03 P, about 0.3 S, about 19.0 to about 21.0 Cr, about 9.0 to about 11.0 Ni, about 14.0 to about 16.00 W, about 3.0 Fe, and Bal. Co.

- the implant comprises a material comprising at most the following percentages by weight: about 0.025 C, about 0.15 Mn, about 0.15 Si, about 0.015 P, about 0.0 IS, about 19.0 to about 21.0 Cr, about 33 to about 37 Ni, about 9.0 to about 10.5 Mo, about 1.0 Fe, about 1.0 Ti, and Bal. Co.

- the substrate comprises a material comprising L605 alloy.

- the substrate comprises a material comprising a platinum chromium alloy instead of a cobalt-chromium alloy.

- the substrate comprises a material comprising MP35N alloy.

- the substrate comprises a material comprising the following percentages by weight: about 35 Ni, about 35Cr, about 20 Co, and about 10 Mo. In some embodiments, the substrate comprises a material comprising a cobalt chromium nickel alloy. In some embodiments, the substrate comprises a material comprising Elgiloy.RTM./Phynox.RTM.. In some embodiments, the substrate comprises a material comprising the following percentages by weight: about 39 to about 41 Co, about 19 to about 21 Cr, about 14 to about 16 Ni, about 6 to about 8 Mo, and Balance Fe. In some embodiments, the substrate comprises a material comprising a platinum chromium alloy. In some embodiments, the substrate comprises an alloy as described in U.S. Pat. No.

- the substrate comprises an alloy as described in U.S. patent application Ser. No. 11/780,060 incorporated in its entirety herein by reference.

- the substrate comprises a material comprising stainless steel, 316L stainless steel, BioDur.RTM. 108 (UNS S29108), 304L stainless steel, and an alloy including stainless steel and 5-60% by weight of one or more radiopaque elements such as Pt, IR, Au, W, PERSS.RTM. as described in U.S. Publication No. 2003/001830 incorporated in its entirety herein by reference, U.S. Publication No.

- nitinol a nickel-titanium alloy, cobalt alloys, Elgiloy.RTM., L605 alloys, MP35N alloys, titanium, titanium alloys, Ti-6A1-4V, Ti- 50Ta, Ti-lOIr, platinum, platinum alloys, niobium, niobium alloys, Nb-lZr, Co-28Cr-6Mo, tantalum, and tantalum alloys.

- Other examples of materials that are comprised in the device (or substrate thereof) are described in U.S. Publication No. 2005/0070990 incorporated in its entirety herein by reference, and U.S. Publication No.

- Subjects into which biomedical implants of the invention may be applied or inserted include both human subjects (including male and female subjects and infant, juvenile, adolescent, adult and geriatric subjects) as well as animal subjects (including but not limited to pig, rabbit, mouse, dog, cat, horse, monkey, etc.) for veterinary purposes and/or medical research.

- the biomedical implant is an expandable intraluminal vascular graft or stent (e.g., comprising a wire mesh tube) that can be expanded within a blood vessel by an angioplasty balloon associated with a catheter to dilate and expand the lumen of a blood vessel, such as described in U.S. Pat. No. 4,733,665 to Palmaz.

- an expandable intraluminal vascular graft or stent e.g., comprising a wire mesh tube

- the substrate is an interventional device.

- An "interventional device” as used herein refers to any device for insertion into the body of a human or animal subject, which may or may not be left behind (implanted) for any length of time including, but not limited to, angioplasty balloons, cutting balloons.

- the substrate is a diagnostic device.

- a "diagnostic device” as used herein refers to any device for insertion into the body of a human or animal subject in order to diagnose a condition, disease or other of the patient, or in order to assess a function or state of the body of the human or animal subject, which may or may not be left behind (implanted) for any length of time.

- the substrate is a surgical tool.

- a "surgical tool” as used herein refers to a tool used in a medical procedure that may be inserted into (or touch) the body of a human or animal subject in order to assist or participate in that medical procedure.

- Stability refers to the stability of the drug in a composition in its final product form, whether or not it is deposited on a substrate (e.g., stability of the drug in a coated stent).

- the term “stability” and/or “stable” in some embodiments is defined by 5% or less degradation of the drug in the final product form.

- the term stability in some embodiments is defined by 3% or less degradation of the drug in the final product form.

- stability in some embodiments is defined by 2% or less degradation of the drug in the final product form.

- stability in some embodiments is defined by 1% or less degradation of the drug in the final product form.

- Polymer refers to a series of repeating monomeric units that have been cross-linked or polymerized. Any suitable polymer can be used to carry out the present invention. It is possible that the polymers of the invention may also comprise two, three, four or more different polymers. In some embodiments of the invention only one polymer is used. In certain embodiments a combination of two polymers is used. Combinations of polymers can be in varying ratios, to provide compositions with differing properties.

- Polymers useful in the compositions, devices and methods of the present invention include, for example, stable or inert polymers, organic polymers, organic-inorganic copolymers, inorganic polymers, bio absorbable, bioresorbable, resorbable, degradable, and biodegradable polymers.

- the composition comprises a polymer.

- the composition comprises an inverse thermo sensitive polymer.

- thermo sensitive polymers which are liquid at low temperatures, rapidly transition to gel at physiological temperature. This transition may occur very quickly over approximately one half of a degree Celsius in some embodiments, and this transition temperature can be altered with various compositions, concentrations and buffer solutions.

- the aqueous, biocompatible polymer is reversible back to a liquid via cooling and is dissolvable (thus such polymers may be referred to as reverse thermo sensitive polymer).

- These polymers are composed of tri-block polymers with two hydrophilic chains connected by a hydrophobic chain. The rapid viscosity transition occurs in response to heat which causes the polymer chains to deform and the hydrophilic arms to align. This leads to the formation of micelles and a subsequent phase change to a viscous gel. The resulting gel is dissolvable and is also reversible back to a liquid with cooling.

- the polymers used herein in some embodiments have unique surfactant abilities and extremely low toxicity and immunogenic responses. They may have low acute oral and dermal toxicity and low potential for causing irritation or sensitization, and the general chronic and sub- chronic toxicity is low. They have been found to enhance the therapeutic effect of drugs, and the gene transfer efficiency mediated by adenovirus. Some of these polymers have been considered for various cardiovascular applications, as well as in sickle cell anemia.

- the polymer comprises poloxamer.

- poloxamer 188 Several members of this class of polymer, poloxamer 188, poloxamer 407, poloxamer 338, poloxamines 1107 and 1307 show inverse thermo sensitivity within the physiological temperature range.

- these polymers are members of a class that are soluble in aqueous solutions at low temperature, but gel at higher temperatures.

- Poloxamer 407 is a biocompatible polyoxypropylene-polyoxy ethylene block copolymer having an average molecular weight of about 12,500 and a polyoxypropylene fraction of about 30%; poloxamer 188 has an average molecular weight of about 8400 and a polyoxypropylene fraction of about 20%; poloxamer 338 has an average molecular weight of about 14,600 and a polyoxypropylene fraction of about 20%; poloxamine 1,107 has an average molecular weight of about 14,000, poloxamine 1307 has an average molecular weight of about 18,000. Polymers of this type are also referred to as reversibly gelling because their viscosity increases and decreases with an increase and decrease in temperature, respectively.

- the polymer comprises poloxamines, e.g., poloxamine 1307 and 1107, which also display inverse thermo sensitivity.

- Certain embodiments comprise poly(ethyleneoxide)/poly(propyleneoxide) block copolymers which have reversible gelling properties have these properties such as Pluronic (RTM) poloxamers and Tetronic (RTM) poloxamines (BASF, Ludwigshafen, Germany) and generically known as poloxamers and poloxamines, respectively. See U.S. Pat. Nos. 4,188,373, 4,478,822 and 4,474,751.

- the average molecular weights of the poloxamers used in certain embodiments range from about 1,000 to greater than 16,000 daltons. Because poloxamers noted herein may be products of a sequential series of reactions, the molecular weights of these individual poloxamer molecules form a statistical distribution about the average molecular weight. In addition, commercially available poloxamers contain substantial amounts of poly(oxyethylene) homopolymer and

- poly(oxyethylene)/poly(oxypropylene diblock polymers The relative amounts of these byproducts increase as the molecular weights of the component blocks of the poloxamer increase. Depending upon the manufacturer, these byproducts may constitute from about 15 to about 50% of the total mass of the polymer.

- the inverse thermo sensitive polymer used in some embodiments can include a therapeutic agent such as anti-angiogenic agents, hormones, anesthetics, antimicrobial agents (antibacterial, antifungal, antiviral), anti-inflammatory agents, diagnostic agents, or wound healing agents.

- a therapeutic agent such as anti-angiogenic agents, hormones, anesthetics, antimicrobial agents (antibacterial, antifungal, antiviral), anti-inflammatory agents, diagnostic agents, or wound healing agents.

- low concentrations of dye such as methylene blue

- fillers can be added to the inverse thermo sensitive polymer.

- the active agent comprises a polymer.

- the polymer comprises at least one of polyalkyl methacrylates, polyalkylene-co-vinyl acetates, polyalkylenes, polyurethanes, polyanhydrides, aliphatic polycarbonates, polyhydroxyalkanoates, silicone containing polymers, polyalkyl siloxanes, aliphatic polyesters, polyglycolides,

- polylactides polylactide-co-glycolides, poly(e-caprolactone)s, polytetrahalooalkylenes, polystyrenes, poly(phosphasones), copolymers thereof, and combinations thereof.

- the polymer is capable of becoming soft after implantation, for example, due to hydration, degradation or by a combination of hydration and degradation.

- the polymer is adapted to transfer, free, and/or dissociate from a delivery device when at the intervention site due to hydrolysis of the polymer.

- the composition comprises a bioabsorbable polymer that is capable of resorbtion in at least one of: about 1 day, about 3 days, about 5 days, about 7 days, about 14 days, about 3 weeks, about 4 weeks, about 45 days, about 60 days, about 90 days, about 180 days, about 6 months, about 9 months, about 1 year, about 1 to about 2 days, about 1 to about 5 days, about 1 to about 2 weeks, about 2 to about 4 weeks, about 45 to about 60 days, about 45 to about 90 days, about 30 to about 90 days, about 60 to about 90 days, about 90 to about 180 days, about 60 to about 180 days, about 180 to about 365 days, about 6 months to about 9 months, about 9 months to about 12 months, about 9 months to about 15 months, and about 1 year to about 2 years.

- the polymers of the present invention may be natural or synthetic in origin, including gelatin, chitosan, dextrin, cyclodextrin, Poly(urethanes), Poly(siloxanes) or silicones,

- Poly(acrylates) such as [rho]oly(methyl methacrylate), poly(butyl methacrylate), and Poly(2- hydroxy ethyl methacrylate), Poly( vinyl alcohol) Poly(olefms) such as poly( ethylene),

- [rho]oly(isoprene), halogenated polymers such as Poly(tetrafluoro ethylene) - and derivatives and copolymers such as those commonly sold as Teflon(R) products, Poly(vinylidine fluoride), Poly( vinyl acetate), Poly( vinyl pyrrolidone), Poly( acrylic acid), Polyacrylamide, Poly(ethylene-co- vinyl acetate), Poly(ethylene glycol), Poly(propylene glycol), Poly(methacrylic acid); etc.

- Suitable polymers also include absorbable and/or resorbable polymers including the following, combinations, copolymers and derivatives of the following: Polylactides (PLA), Polyglycolides (PGA), PolyLactide-co-glycolides (PLGA), Polyanhydrides, Polyorthoesters, Poly(N-(2- hydroxypropyl) methacrylamide), Poly(l-aspartamide), including the derivatives DLPLA— poly(dl-lactide); LPLA— poly(l-lactide); PDO— poly(dioxanone); PGA-TMC— poly(glycolide-co-trimethylene carbonate); PGA-LPLA— poly(l-lactide-co-glycolide); PGA- DLPLA— poly(dl-lactide-co-glycolide); LPLA-DLPLA— poly(l-lactide-co-dl-lactide); and PDO-PGA-TMC— poly(glycolide-co

- Copopolymer refers to a polymer being composed of two or more different monomers.

- a copolymer may also and/or alternatively refer to random, block, graft, copolymers known to those of skill in the art.

- a "gel” may refer to a composition having a viscosity such that the composition remains static, i.e. does not migrate or does not move once deployed in the body. Such a composition may remain in the location of application +/- one distance equal to the size of the implant for at least 1 minute, at least 1 hour, at least 1 day, at least 1 month, at least 6 months, at least about 1 minute, at least about 1 hour, at least about 1 day, at least about 1 month, or at least about 6 months.

- a "gel” is a colloid in which the solid disperse phase forms a network in combination with the fluid continuous phase, resulting in a viscous semirigid sol.

- a "gel” is a colloid in a more solid form than a sol.

- a “gel” is a sol in which the solid particles are meshed such that a rigid or semi-rigid mixture results.

- a "gel” is a solid, jelly-like material that can have properties ranging from soft and weak to hard and tough. Gels may be defined as a substantially dilute cross-linked system, which exhibits no flow when in the steady-state. By weight, gels may be mostly liquid, yet they behave like solids due to a three-dimensional cross-linked network within the liquid. It is the crosslinks within the fluid that give a gel its structure (hardness) and contribute to stickiness (tack). In this way gels may be a dispersion of molecules of a liquid within a solid in which the solid is the continuous phase and the liquid is the discontinuous phase.

- the gel may be a hydrogel.

- Hydrogel also called aquagel

- Hydrogel is a network of polymer chains that are hydrophilic, sometimes found as a colloidal gel in which water is the dispersion medium.